Date:2024.04.30

Visits:528

Date:2024.04.30

Visits:528

On 25th April, the 3rd International Forum on Compound Semiconductors, jointly organised by the Taiwan Electronic Equipment Association (TEEA) and the College of Engineering of National Taiwan University (NTU), came to a successful conclusion at the Nangang Exhibition Hall in Taipei. Aiming to promote the compound semiconductor industry in Taiwan, the forum invited heavyweight lecturers from home and abroad to exchange views on the application market of "compound semiconductors", manufacturing equipment, test equipment, and fourth-generation compound semiconductors and other related topics.

As a special guest, JiaWei-Lin,

Vice President of Marketing of Semight, participated in the forum

and gived a speech on "Semight Turn-Key Solution for SiC Test and

Reliability", sharing Semight' complete solution and

professional experience in SiC test.

The theme of this year's forum is

"Compound Semiconductors", and experts from ROHM, SiCEV, Coherent,

Infineon, Yole Intelligence, and other major manufacturers were invited to share

specialized information on the trend of new-generation compound semiconductor

technology. According to professional forecasts, SiC industry in 2023 - 2029

years, with a compound annual growth rate of 25% of rapid growth, China's

production capacity will be greatly increased.

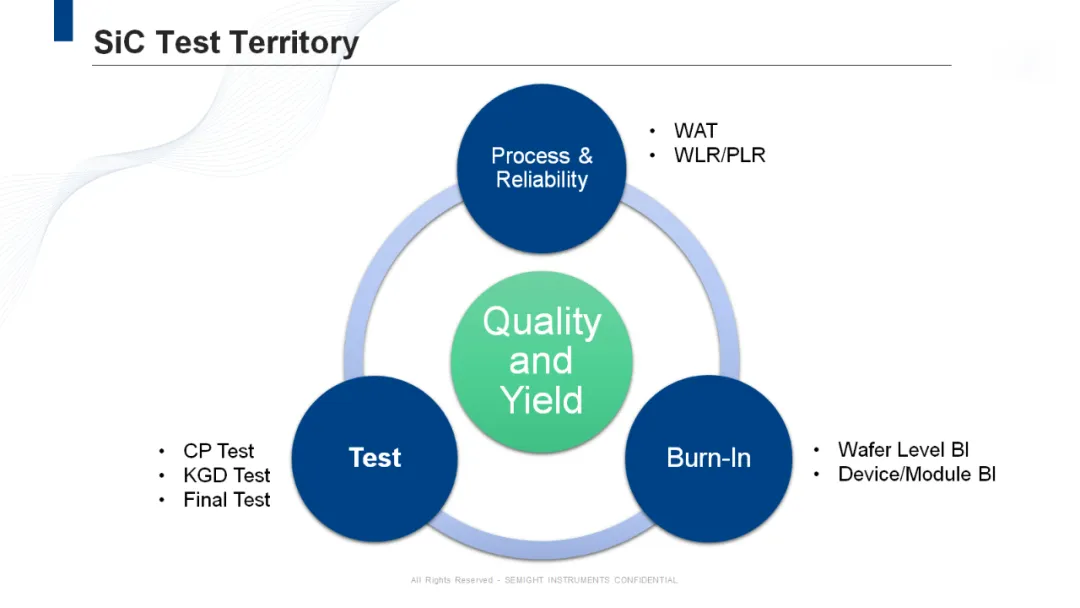

It is well known that SiC has a strong

breakdown force field and higher thermal conductivity, which allows the device

to operate efficiently at high voltages and up to 175°C. However, there are

very obvious reliability issues with current SiC fabrication. For example, more

extrinsic defects, threshold voltage drift, short-circuit capability of SiC

MOSFETs, bipolar degradation reducing the active area of SiC devices, and so

on. Therefore SiC device products need to undergo wafer-level burn-in tests

such as HTRB, HTGB, TC, AC/PCT, etc., and KGD-level tests for high and low

power devices with critical static characteristics (Vds, Igss, Idss, Rds,

etc.), dynamic characteristics (Isc, td(in), td(off), Tr, Eon, etc.), and so

on, before they are put on the market.

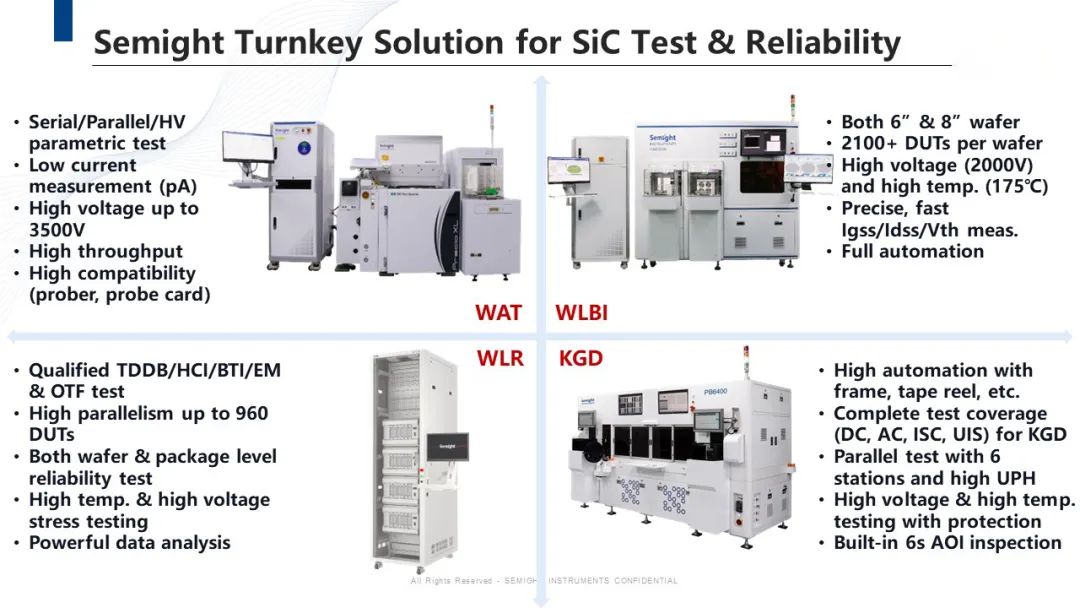

Over the years, Semight has ploughed into the core areas of SiC manufacturing and testing processes, insisted on independent research and development of core instruments, and successively launched High-Voltage Serial Parameter Test System WAT6300, Wafer-Level Burn-in System WLBI3800, SiC KGD Test System PB6400, Multi-site Wafer-Level Reliability Test System WLR0010, and other SiC-related test equipment, which provides a comprehensive turnkey solution for the research and development, production and application of SiC materials.

With

long-term high intensity R&D investment, existing R&D and production

sites of more than 20,000m2, more than 50% of R&D personnel and 30% of R&D investment, Semight is

the industry's leading supplier of SiC Wafer Burn-in and KGD Test Systems, and

has made excellent contributions to solving the problem of the " stranglehold " of

high-end test instrumentation in China.

Service hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password