Products

Optical Network Test

Optical communication network plays an important role in the rapid development of big data, cloud computing, 5G communication and other markets.

Semight offers various of instruments for optical Transceiver/Component testing, including wide bandwidth sampling oscilloscope, NRZ/PAM4 bit error ratio tester , burst error ratio tester, fast wavelength meter, optical spectrum analyzer, high precise source measure unit, 400G network analyzer ,optical power meter, optical attenuator, optical switch etc. Provide cost-effective complete solutions.

The Sampling Oscilloscope is based on equivalent sampling and eye reconstruction technology, achieving precise and cost-effective measurements for high speed photoelectric digital signals. By selecting from a range of filter options, it can support optical eye diagram testing at various data rates.

Details

For the high-speed serial data, the clock information is embedded into the transmitted data stream by data encoding, and the clock information is extracted by clock recovery at the receiver, then the data is sampled by the recovered clock. Therefore, the clock recovery is very important for the transmission and reception of high-speed serial signals.

Details

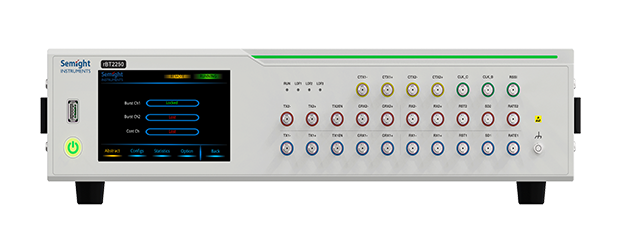

In the PON system, the OLT downstream data is sent in broadcast continuous mode, and the ONU upstream data is composed of burst mode data packets sent by multiple user terminals in the time division multiple access mode.The performance of OLT receiver can be verified only when the burst error analyzer is in burst mode.

Details

Bit Error Ratio Tester is an instrument for testing and analyzing bit error rates. It is used for bit error detection and alarm monitoring in digital transmission systems, optical fiber communication systems, and digital microwave systems. It is an important tool for bit error testing of optical modules and optical devices in the development and production.

Details

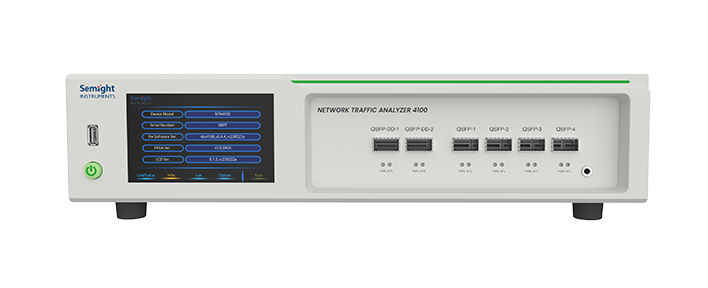

In recent years, with the application of PAM4 optical module, the introduction of mandatory FEC makes optical module manufacturers need to add MAC layer Traffic test in addition to PRBS service. Different from the traditional bit error meter, the traffic meter can support Ethernet packet test, real FEC analysis based on Ethernet frame and standard 2544 protocol test. The switch can also be connected for running test, so that the network tester has more application space than the error code analyzer.

Details

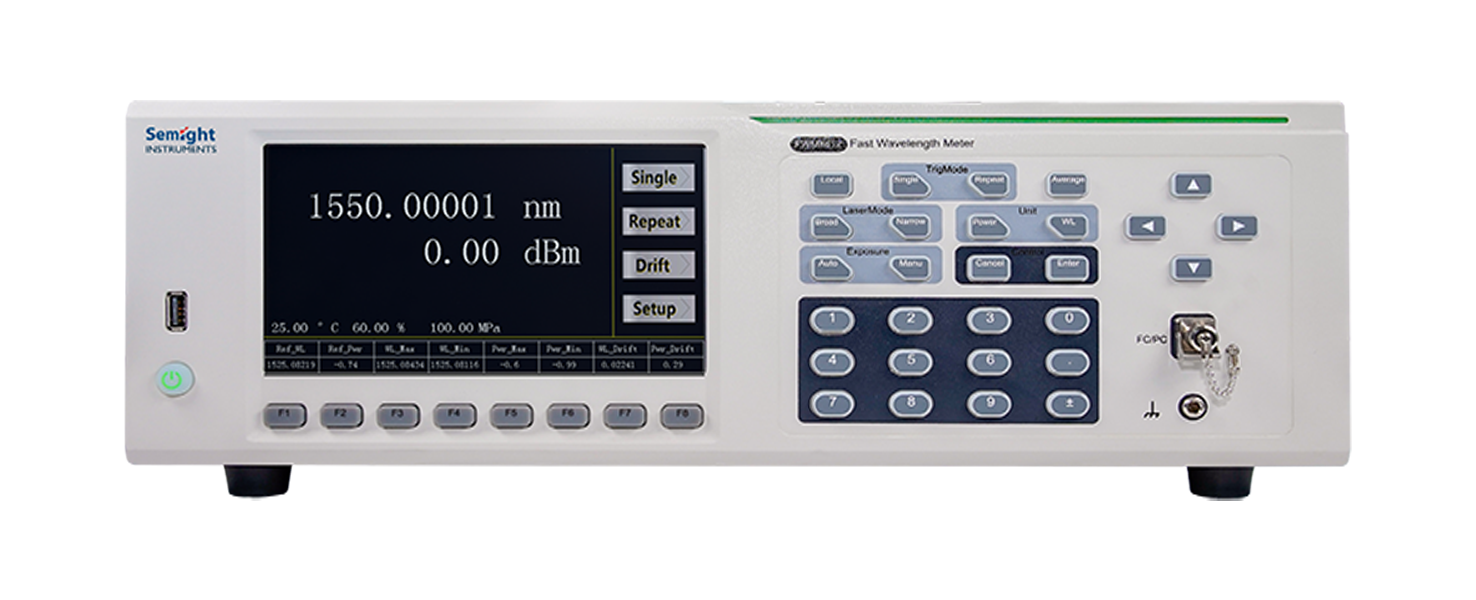

With the increasing demand for communication data, a large number of coherent communication modules based on wavelength-tunable lasers are used in the transmission backbone network.

Details

Optical power meter, optical switch, and optical attenuator are used for optical power measurement, optical path switching, optical power adjustment and other application scenarios. They are basic instruments for optical communication systems.

Details

Semight-we can provide high-end test instruments including High-Speed Bit Error Tester, Network Tester,Optical Communication, High-Precision Wavelength Meter, Spectrometer etc.

DetailsProducts

Electronic Measurement

The high-precision source meter integrates the functions of voltage source, current source, voltmeter, ampere meter, and electronic load in one, which is widely used in high-precision IV test and measurement for various discrete components, photovoltaic, new energy, battery and other industries. Semight Instrument provides high-precision benchtop source meters and plug-in PXIe source meter modules of standard PXIe chassis, fully meeting the application of various test scenarios.

The high-precision source meter integrates the functions of voltage source, current source, ammeter, voltmeter and load, and has a wide range of applications in semiconductor discrete components, photovoltaics, automobiles, batteries, Nano - characterization devices and other fields.

Details

PXIe Source Meter Module, supports most of the PXIe chassis, It is convenient to integrate and extend to large-scale integrated test system.

Details

The high-voltage SMU is designed for testing the characteristics of high-voltage electronic and power semiconductor devices, and is widely used in testing and research fields such as power semiconductor characteristics, GaN, SiC characterization, composite materials, and high-voltage leakage current.

Details

RM1010-LLC 4-slot semiconductor switch matrix can meet high-speed semiconductor test applications with S3022F benchtop or S2012C PXle plug-in card source measure unit.

Details

Supports up to 48 pins and the number of pins can be flexibly configured. Compatible with industry probe card architecture, supporting all types of universal probe station control; Self-developed sub-pA level accuracy source measure unit; Support serial and parallel test

Details

Wafer Level Reliability testing technology can be used to provide rapid feedback on process control information about the reliability of semiconductor process products. The purpose of wafer level reliability testing is to measure changes in the materials that make up semiconductor devices.

DetailsProducts

Optical Chip Test

Burn-in testing of laser is an important method to ensure the reliability of laser. Through the test of COC or bare die, the early failure of laser caused by the defects in the process of laser production can be screened out in advance. Semight Instrument provides a complete solution from bare die to COC, from high temperature(150℃ or higher) to low temperature (-40℃), with CoC automatic loading and unloading system, forming a complete test solution, Semight Instrument's laser chip burn-in/load/unload test system has been widely recognized by the market.

Semiconductor lasers have the excellent characteristics of ultra-small, high-efficiency and high-speed operation, is the core devices of optical communication. Semiconductor lasers must be tested for various parameters before leaving the factory, including before and after the burn-in of the product characteristics must be strictly controlled, in order to ensure the reliability of the product and service life.

Details

Lasers undergo burn-in testing during the manufacturing process to identify and remove defective devices that may cause early failure. Semiconductor lasers come in a variety of packaging styles and power levels, which complicates semiconductor laser testing.

Details

Silicon photonics is a large-scale integration technology of silicon-based optoelectronics based on photons and electronics as information carriers, which can greatly improve the performance of integrated chips, and is the basic supporting technology for emerging industries such as big data, artificial intelligence, and mobile communications, and can be widely used in big data centers, 5G, Internet of Things and other industries. Silicon photonics technology uses the working mechanism and optoelectronic characteristics of photons, electronics and optoelectronic devices in silicon materials, and uses micro-nano processing technology compatible with integrated circuits to develop and manufacture optoelectronic chips on silicon wafers.

DetailsProducts

Power Semiconductor Test

The semiconductor front-end test is mainly used in the wafer processing to check whether the processing parameters of the wafer products meet the design requirements or there are defects affecting the yield after each step of the manufacturing process. The semiconductor back-end test equipment is mainly used after wafer processing to check whether the performance of the chip meets the requirements, which belongs to the electrical performance test. Semight Instrument provide integrated solutions such as wafer burn in and known good die tester, improve test efficiency and reduce test cost.

Wafer Level Burn-In System is designed to perform HTGB and/or HTRB burn-in and test for SiC/GaN wafer. The burn-in system can be widely used in research and development, mass production and quality monitoring, and can strictly screen chips with risks in advance to ensure the reliability of packaged products.

Details

The KGD test system is mainly used for the dynamic and static parameter testing of power bare chips, which can screen DIE after the splinter and improve the cumulative yield of the module package.

Details

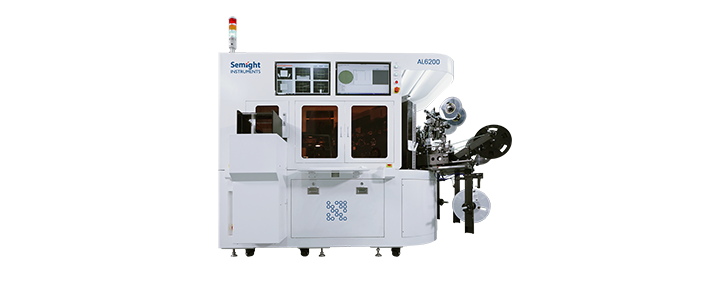

Semight AL6200 Die Sorting system is mainly used in power chip die level visual inspection and sorting. The sorting condition is according to the different test specification and visual inspection.

DetailsService hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password