Service

Service

3. Response time and response method: During the warranty period, if the equipment malfunctions, we will arrive at the customer's repair site within 8 hours locally and within 24 hours for other provinces after receiving the user's repair request. If the equipment cannot be used normally after multiple repairs due to performance issues during the warranty period, we will replace it with a new device free of charge. After the warranty period, if the product malfunctions, we can send a technical support engineer for free on-site service. If parts need to be replaced, they will be supplied at the most favorable market prices. We have resident technical support engineers in many locations across the country to respond to related needs promptly.

4. Service working hours: For all products supplied, we adhere to 24/7 service, every day of the work.Add: No. 1508, Xiangjiang Road, High-tech Zone, Suzhou City, Jiangsu Province, China

Q&A

Q&A

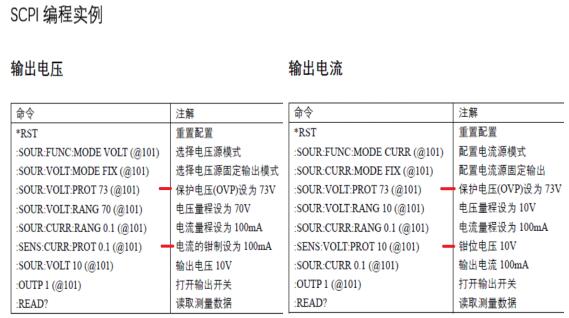

Before init, ensure that the source output status is on

Service hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password