PXIe Source Meter Unit

S2016C

Single channel PXIe precision power supply/measurement unit

Semight S2016C is a compact and cost-effective single channel PXIe power supply/measurement unit that can simultaneously output and measure voltage and current. It can provide a maximum output of ± 200V, ± 1A (DC), ± 3A (pulse), and 20W constant power. It supports traditional SMU SCPI commands, making the migration of test code easy and fast. It supports existing PXIE chassis in large factories, supports multi card synchronization, and is integrated into production testing systems for use, To improve the testing efficiency of the system and reduce costs.

Features

High-precision

Resolution up to 1fA/100nV,

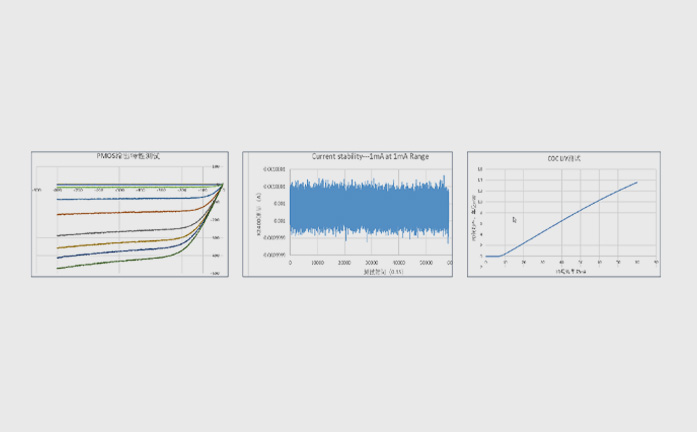

High range, high-speed measurement

±200 V、±1 A(DC),

Adaptive PFC system

Utilize Adaptive PFC

Building a single channel testing system

Based on standard PXIe chassis, easy to expandFeatures and Benefits

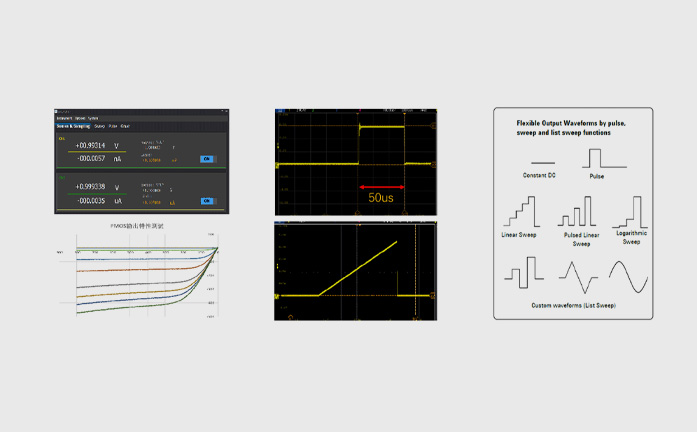

5 functions in one

Voltage source

Test various devices

Capture more measurement data

♦ 6 and a half bit digital resolution: the accuracy is equivalent to a 6 and a half bit digital multimeter

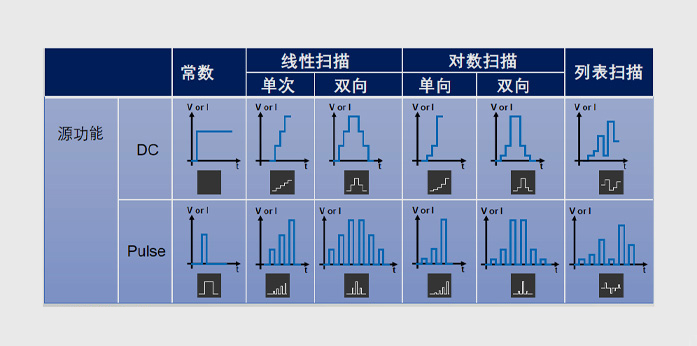

Rich scanning functions

DC I-V output capability

Pulse I-V output capability

|

Voltage accuracy |

Range |

Measurement resolution |

Accuracy (1 year) ± (% reading+offset) |

Typical noise (effective value) 0.1 Hz-10 Hz |

|

±200 V |

100 μV |

0.03%+10 mV |

400 μV |

|

|

±40 V |

10 μV |

0.03%+2 mV |

100 μV |

|

|

±20V |

10 μV |

0.03%+1 mV |

50 μV |

|

|

±2 V |

1 μV |

0.03%+100 μV |

10 μV |

|

|

±0.6 V |

100 nV |

0.03%+50 μV |

2 μV |

|

|

temperature coefficient |

±(0.15 × Accuracy index)/℃ (0℃-18℃, 28℃-50℃) |

|||

|

set time |

<50 μs (Typical value) |

|||

|

overshoot |

<±0.1% (Typical value, Normal, with steps ranging from 10% to 90%, full scale point, resistive load test) |

|||

|

Noise 10Hz-20MHz |

20V voltage source, 1A resistive load, <5 mVrms |

|||

|

Current accuracy |

Range |

Measurement resolution |

Accuracy (1 year) ± (% reading+offset) |

Typical noise (effective value) 0.1 Hz-10 Hz |

|

±3 A1 |

1 μA |

0.03% + 2mA |

20 μA |

|

|

±1 A |

100 nA |

0.03% + 90 μA |

4 μA |

|

|

±100 mA |

10 nA |

0.03% + 9 μA |

600 nA |

|

|

±10 mA |

1 nA |

0.03% + 900 nA |

60 nA |

|

|

±1 mA |

100 pA |

0.03% + 90 nA |

6 nA |

|

|

±100 μA |

10 pA |

0.03% + 9 nA |

700 pA |

|

|

±1 μA |

100 fA |

0.03% + 200 pA |

20 pA |

|

|

±10 nA2 |

10 fA |

0.06% +9 pA |

600 fA |

|

|

±1 nA2 |

1 fA |

0.1% +3 pA |

60 fA |

|

|

±100 pA2 |

1 fA |

0.3% +1 pA |

30 fA |

|

|

temperature coefficient |

±(0.15 × Accuracy index)/℃ (0℃-18℃,28℃-50℃) |

|||

|

set time |

<100 μs (Typical value) |

|||

|

overshoot |

<±0.1% (Typical value, Normal, with steps ranging from 10% to 90%, full scale point, resistive load test) |

|||

1. 3A range only supports pulse mode, with typical accuracy

2. Additional specification conditions: NPLC configured with 10PLC

|

Minimum programmable pulse width |

100 μ S |

|

Pulse width programming resolution |

1 μ S |

|

Pulse width programming accuracy |

± 10 μ S |

|

Pulse width jitter |

2 μ S |

|

Pulse width definition |

As shown in the following figure, the time from the 10% leading edge to the 90% trailing edge |

|

Pulse technical indicators |

Maximum current limit |

Maximum pulse width |

Maximum duty cycle |

|

1 |

0.1 A/200 V |

DC, unlimited |

100% |

|

2 |

1 A/20 V |

DC, unlimited |

100% |

|

3 |

3 A/66.6 V |

1 ms |

5% |

|

4 |

3 A/160 V |

400 μ S |

2% |

|

Output |

Maximum output |

Typical rise time1 |

Typical stability time2 |

Test load |

|

Voltage source |

160 V |

800 μ S |

1.2 ms |

Empty |

|

5 V |

40 μ S |

100 μ S |

Empty |

|

|

Current source |

3A~100 μ A |

90 μ S |

250 μ S |

With full load3 |

|

1 μ A |

300 μ S |

600 μ S |

With full load3 |

|

|

10 nA |

5 ms |

10 ms |

With full load3 |

|

|

1 nA |

10 ms |

50 ms |

With full load3 |

|

|

100 pA |

100 ms |

500 ms |

With full load3 |

1. The time required for the pulse front to travel from 10% to 90%

2. The time required for the pulse to reach 1% of the final value

3. Test conditions: Normal pure resistance full load voltage rises to 6V

|

Output |

Range |

Typical output establishment time1 |

Test conditions |

||

|

Fast2 |

Normal |

Slow |

|||

|

Voltage source |

200 V |

<five hundred μ S |

<nine hundred μ S |

<2 ms |

The time required to reach within 0.1% of the final value under open circuit load conditions. Stepping is within the range of 10% to 90% |

|

40 V |

<two hundred μ S |

<four hundred μ S |

<nine hundred μ S |

||

|

20 V |

<sixty μ S |

<one hundred μ S |

<five hundred μ S |

||

|

2 V |

<fifty μ S |

<fifty μ S |

<fifty μ S |

||

|

Current source |

3 A~100 μ A |

<fifty μ S |

<one hundred μ S |

<0.8 ms |

Under normal conditions and full load, the voltage output reaches 6V. Reaching within 0.1% of the final value (for 3 A The time required for a range of 0.3%. Step is 10% of the range to 90% |

|

1 μ A |

<three hundred μ S |

<four hundred μ S |

<1 ms |

||

|

10 nA |

<10 ms |

<10 ms |

<10 ms |

||

|

1 nA |

<50 ms |

<50 ms |

<50 ms |

||

|

100 pA |

<500 ms |

<500 ms |

<500 ms |

||

1. Output conversion rate: Fast, Normal, Slow. Users can adjust APFC parameters based on load characteristics to obtain appropriate setup time or stability

2. Fast mode may produce significant overshoot under different range or load conditions. It is recommended to use normal or slow mode for overshoot sensitive devices

Similar recommendation

Service hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password