Low Leakage Switch Matrix

RM1010-LLC

Low Leakage Switch Matrix

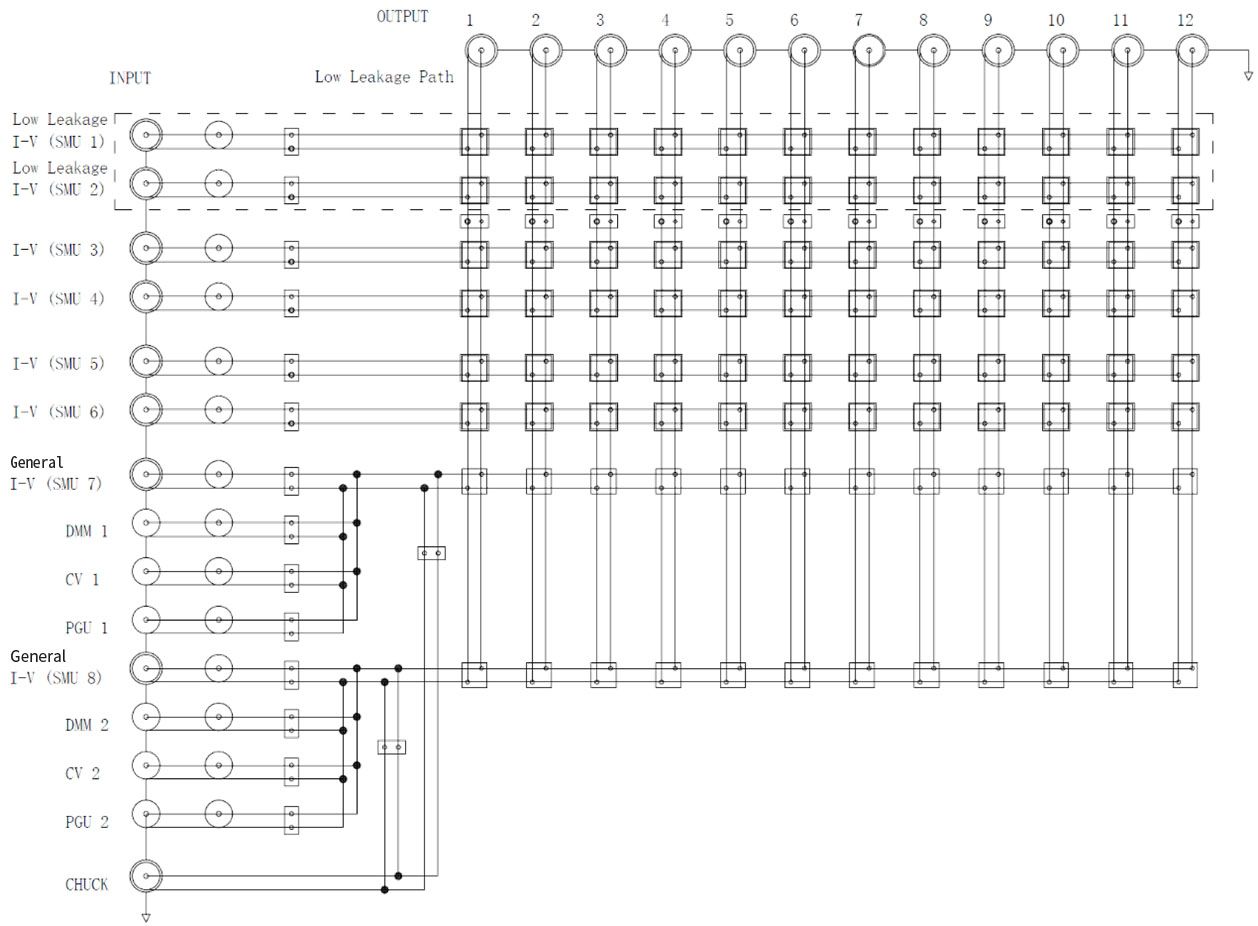

RM1010-LLC 4-slot semiconductor switch matrix can meet high-speed semiconductor test applications with S3022F benchtop or S2012C PXle plug-in card source measure unit. Easy to use GUI is also speeding up the development for new test functions and simplifying system integration. RM1010-LLC supports traditional SCPI commands, making the migration of test code easy and fast, it can support multi-machine parallel connection to improve system test efficiency and reduce costs.

Feature

Precise, consistent results

14 inputs and 48 outputs

High resolution

20 pA measurement resolution

Rapid measurement

Instantaneous current settling time<3.5 seconds(<450 fA,10V step)

High-speed signal measurement

10 MHz Bandwidth (at - 3dB)

Flexible configuration

Modular design

LED display panel

Easy to use front panel design

PC GUI control software

Remote measurement and control from PC

Convenient testing

Supports traditional SCPI commandsFunctions and advantages

Precise, consistent results

14 inputs and 48 outputs (up to 96 cross-nodes in low leakage matrix configuration) 20 pA measurement resolution(With S3012H, S3022F, S2011C or S2012C SMU)

|

Secification |

|

2(Low Leakage I-V Port) 6(General I-V Port) 2(C-V Port) 2(DMM Port) 2(PGU Port) |

| Ouput channels | 12/24/36/48 | |

| Max. Current rating | 1 A | |

| Max. Voltage rating |

200V(Channel to Ground) 300V (Channel to Channel) |

|

|

|

0.6 Ω(Low Leakage I-V Port) 1.0 Ω(General I-V Port) 1.0 Ω(C-V, HF Port) |

|

|

|

1013 Ω(Low Leakage I-V Port) 1012 Ω(General I-V Port) 109 Ω(C-V, HF Port) |

|

|

|

Offset current |

<0.1pA(Low Leakage I-V Port) <1000pA(General I-V Port) |

|

|

<80uV(Low Leakage I-V Port) <110uV(General I-V Port) <110uV(C-V, HF Port) |

|

| Channel Crosstalk Capacitance | <0.3pF/CH | |

| Additional C measurement Error | <±1%±0.5pF(C-V Port) | |

|

Supplemental Information |

||

| Communication interface | USB/LAN | |

| Power Requirements | 100/120/220/240 V ± 10%, 47 Hz to 63 Hz | |

| Maximum VA | 100W | |

| Bandwidth(@ -3dB) | <10MHz (C-V, HF Port) | |

| Relay contact life | >108 times | |

| Settling time | < 3.5s(< 450 fA,10V step) | |

| Environment | Indoor use | |

| Work condition | 0℃~+40℃,5%~80 % (no condensation) | |

| Storage condition | -40℃~70℃,5%~90 % (no condensation) | |

| Altitude condition |

Operating: 0 m~2000 m Storage:0 m ~4600 m |

Similar recommendation

Service hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password