2022.08.26

2022.08.26 Necessity of wafer reliability test in vehicle specification SiC chip:

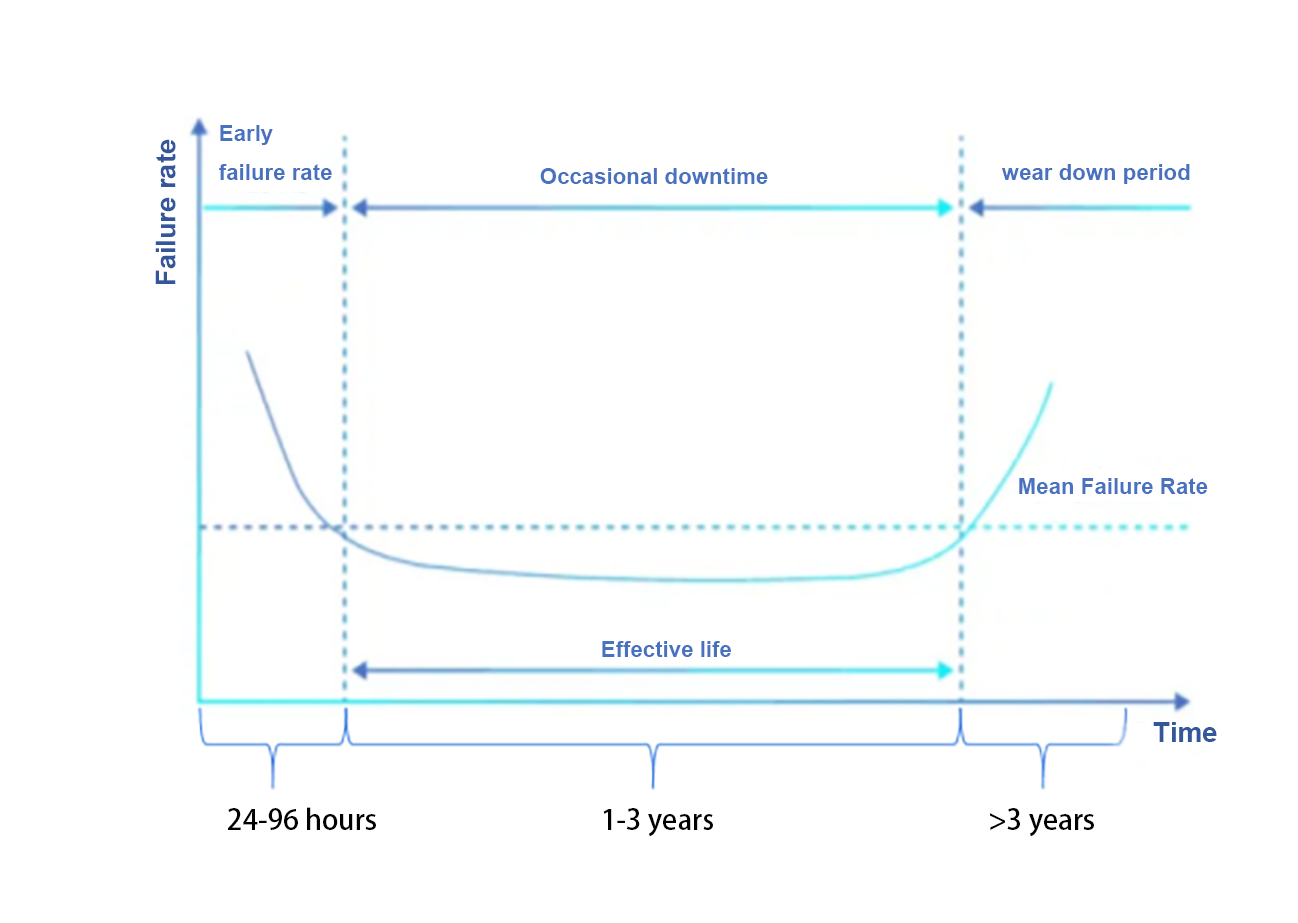

According to the bathtub curve theory, any electronic component will have a high failure rate at the beginning of its life cycle, and the failure rate will obviously drop to the stable period with the passage of time.

The SiC Power Module of the vehicle gauge is different from the ordinary to package device. There is only one die inside the ordinary to package device. If it fails, only a single device needs to be replaced. However, the SiC Power Module of the vehicle gauge protects dozens of dies. If one die fails, the performance of the whole module will be affected. Therefore, if bad dies can be screened out from the wafer in advance, the yield of packaged modules and the life cycle of modules can be greatly improved.

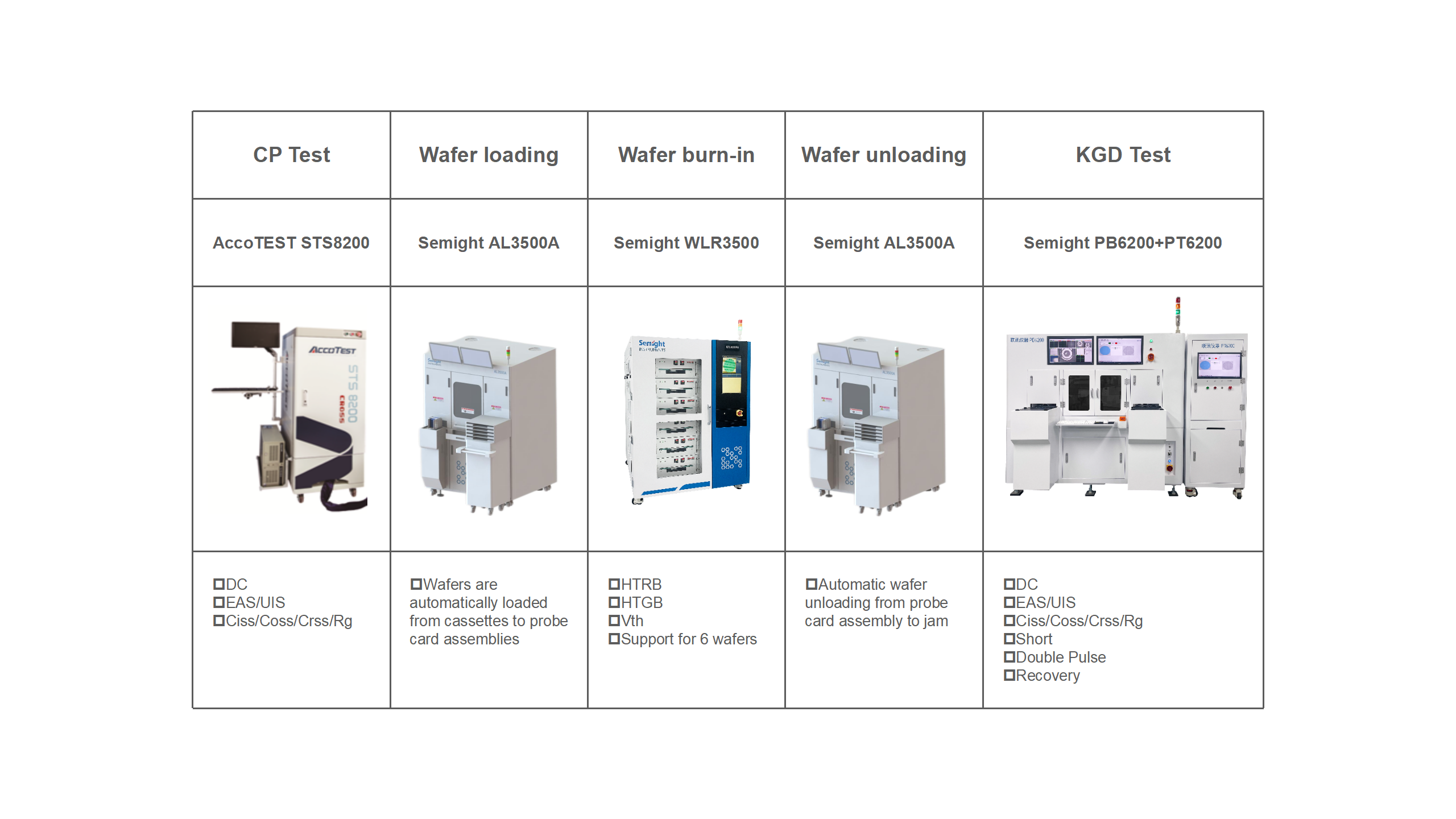

Semight provides a complete set of solutions for wafer aging, including CP loading machine wafer aging unloading machine KGD to solve the complete set of test solutions before packaging into modules.

Wafer aging machine: WLR3500 parameters

Suitable for GaN, SiC wafer aging

Up to 12 GB or 6 GB & RB wafers can be aged at the same time

Each drawer has independent temperature control and power up

Htgb voltage + / - 50V, HTRB voltage 3000V

The whole system supports up to 8544 (712 * 12) channels (htgb)

Leakage current resolution during aging test: 0.1na

Perfect hardware circuit to protect each circuit

Highly reliable gas protection at > 4 bar atmospheric pressure

Support IGSS, IDSs and Vth tests

Temperature range: rt-200c

The software supports test plan meter configuration

The software supports automatic determination of pass / fail

The software supports bin classification according to customer defined rules and generates corresponding map

Service hotline

Follow

Name

Email verfication code

Phone

Password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password