Wafer Level Reliability

EDH3101W

Standard damp heat

Semight Instruments EDH3101W standard damp heat burn-in system can be used in the long-term reliability tests of HBT and pHEMT (enhanced/depleted) devices made of different materials in high temperature and high humidity environments. The Vds/Vce power provided by the EDH3101W standard damp heat burn-in system can be provided by the secondary driver board power supply, and the Vgs/Vbe burn-in voltage can be provided by the self-made adjustable system according to the feedback control of the Ids/Ice current value. During the test, the system can be used to make the Ids/Ic current and Vds/Vce voltage of each test station constant automatically, to ensure that each test station can be automatically adjusted to the same test conditions and to adjust the current at the ds/ce terminal in real time and to monitor the voltage and current of gs/be and ds/ce terminals, thereby, the function of reliability burn-in screening can be implemented.

Feature

High-capacity

A total of 216 dip packages are supported for aging

Complete monitoring parameters

Including monitoring GS / be voltage and current, DS / CE voltage and current

High temperature and high humidity reliability

Constant IDS / ice control aging function

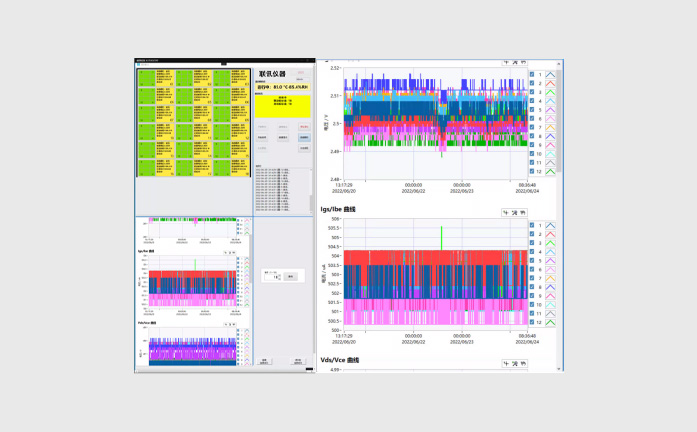

Graphically display different monitoring parameter values

Including temperature, GS / be voltage and current, DS / CE voltage and current

Support software customization development

Can connect to customer MES system and database

Anti stupidity function

Support door opening alarm, door opening power failure, etc

Data protection

Built in UPS power supply to effectively protect the loss of abnormal data during aging

EOS, ESD,EHS

It meets EOS and ESD protection and EHS requirementsFunctions and advantages

The software interface is simple and intuitive

The EDH3101W test software platform of Semight Instruments is a configurable platform with a simple and intuitive user interface.

| System function | Dimension (mm) |

800*2000*1700+1000*2000*1000 |

| Support fixture type | Standard DIP fixture | |

| Number of to supported by the system | 218 | |

| System temperature zone | Two independent temperature zones | |

| SN batch input | Support bar code identification on fixture and batch input of product SN | |

| MES system interface | Support the software to custom, develop and dock with the customer's MES system and database |

|

| Data saving | Save the original test data, calculation results and detailed log of system operation | |

| System power supply | 380V | |

| Temperature control | Temperature rang | Room temperature to 85 ℃ |

Temperature ramp up speed |

>3 ℃ / min (no load) | |

| >1.5 ℃ / min (full load) | ||

| Temperature control accuracy | 0.1℃ | |

| Temperature accuracy | ±1℃ | |

| Temperature uniformity (product position at 9 points in space) | ± 2 ℃ full load (≤ 80 ℃) | |

| Electrical parameters | Drive plate type | Independent operation and control of each channel |

| VGS/VBE Voltage range | -5V~5V accuracy<1%FS | |

| IGS/IBE Current range | -2mA~2mA accuracy<1%FS | |

| VDS/VCE Voltage range | 0~15V accuracy<1%FS | |

| IDS/ICE Current range | 0~100mA accuracy<1%FS | |

Constant IDS/ICE burn-in function |

Automatically adjust VGS / VBE to make IGS / ice constant current aging | |

| Safeguard | Power off under normal operation | Normal |

Power on undernormal operation |

Normal | |

Power failure under mains electricity |

Normal | |

Power on under mains electricity |

Normal | |

| ESD |

Use anti ESD materials Surface resistance:1×10^5Ω< X<1×10^9Ω; Friction voltage:<100V; Grounding; All isolated conductors in the system must be grounded, all instruments must be grounded, the rack must be grounded, and the grounding resistance<4ohm The mouse and keyboard need ESD protection |

|

| Safety | There are no sharp edges and corners and no risk of leakage in the equipment |

|

| Clean | The system is free of chips, paint and rust |

Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password