Laser Diode Burn-in

BI6201

CoC Burn-In System

The BI6201 burn in system is a high-density, multi-functional testing system specifically designed for the verification of the aging lifespan of semiconductor laser chips. The system adopts a modular framework and a large single-layer structure, significantly reducing system costs by integrating multi-channel power supplies, temperature controllers, real-time data acquisition capabilities, as well as standardized drawers and flexible fixture configurations. Customized test fixtures are suitable for various packaging types of semiconductor lasers, such as CoC (Chip on Carrier), TO-Can, etc., of different sizes. The fixtures can be easily replaced to accommodate different device types. The driving circuit of BI6201 features excellent protection networks to prevent any current or voltage overshoot, eliminating potential EOS risks. It also allows setting thresholds for current and voltage, and the system can shut down abnormal channels when the output values exceed the threshold, providing enhanced protection for the tested chips. In addition to integrating protection functions into the control circuit, the system design also considers channel-to-channel isolation performance and electrostatic discharge (ESD) protection.

Feature

SMU drive power supply

Support up to 4224 channels of 4-quadrant SMU drive power supply

Support LIV / EA sweep

Online power monitoring, supporting complete liv/EA sweep

Analytical ability

With ith and DCER analysis ability, test repeatability deviation < 1%

Large capacity

4224 four-quadrant electrical channel design make the system very flexible;Functions and advantages

Special temperature control structure with excellent thermal conductivity

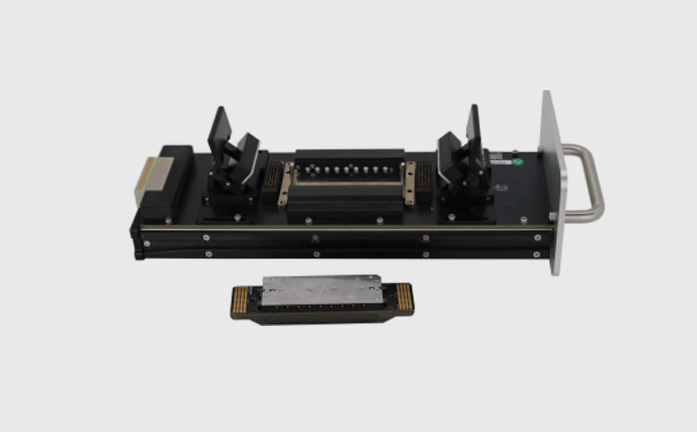

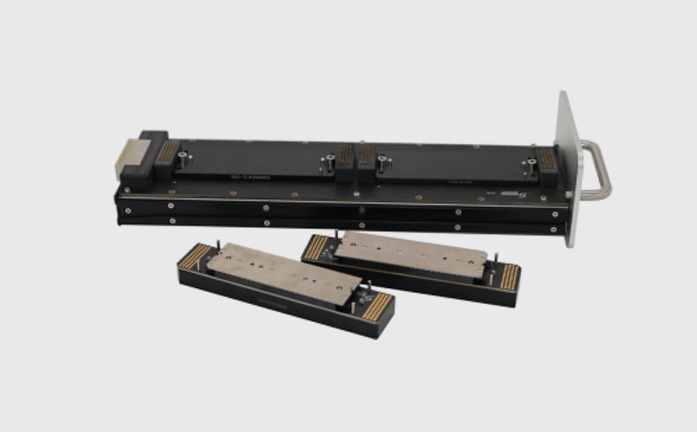

CoC, CoS drawer and clamp

Support automatic current control, automatic power control, safe

CoC, CoS drawer and clamp with online monitoring power (support liv scanning and power measurement)|

System index |

DUT Type | CoC, TO46, TO56 |

|

Fixture type | 48pcs CoC fish bone fixture |

|

|

System capacity |

11 Layers, 44 Drawers, 88 fixtures, total 4224 channels |

|

|

Nitrogen protection |

Nitrogen protection function option can be integrated |

|

|

Power supply |

AC 380V, 50/60Hz 32A |

|

|

Pressure |

0.4-0.6Mpa |

|

|

Weight |

<1000kg |

|

|

Size |

984*1102*2030mm |

Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password