PXIe SMU

S2011C

Single-Channel PXIe Precision SMU

特点

High transmission rate

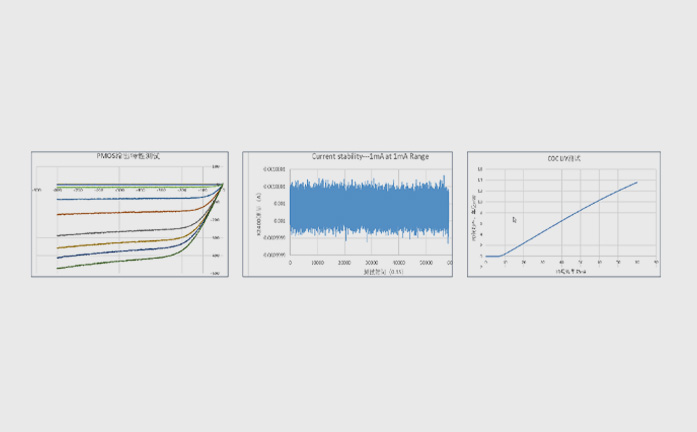

Single channel standard PXIe precision power supply

High range

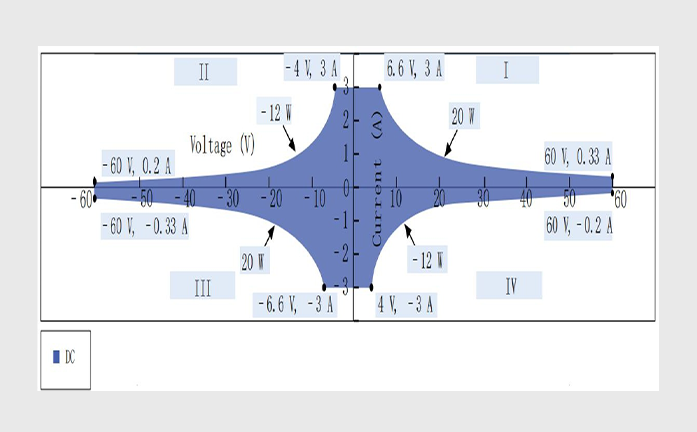

±60 V、±3 A(DC)、±10 A(pulse)

High resolution

The minimum measurement resolution can reach 100fA / 100nV

Easy to expand

It is used in standard PXIe chassis to easily realize multi-channel expansionFunctions and advantages

(5) function in one body

Voltage source

Can test various equipment

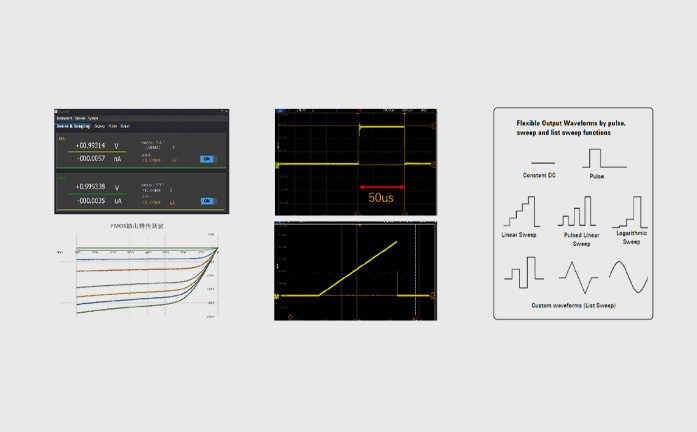

Capture more measurement data

♦ 6.5-digit resolution: Enjoy best-in-class 6.5-digit sourcing and measurement resolution;

Rich scanning function

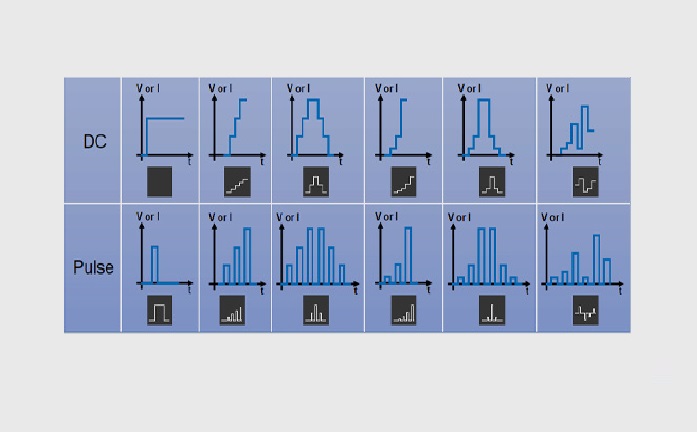

DC I-V output capacity

Pulse I-V output capacity

| Range | Programming resolution |

Accuracy (1 Year) ± (% reading+ offset) |

Typical Noise(RMS) 0.1 Hz-10Hz |

||||

| ±60 V | 10 μV | 0.02%+3 mV | 200 μV | ||||

| ±6 V | 1 μV | 0.02%+0.3 mV | 60 μV | ||||

| ±0.6 V | 100 nV | 0.02%+50 μV | 20 μV | ||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

| Settling time | <50μs (typical) | ||||||

| Overshoot | <±0.1% (Typical.Normal.Step is 10 % to 90 % range, full range, resistive load) | ||||||

| Noise 10Hz-20MHz |

6 V voltage source, 3A resistive load, <5 mVrms |

||||||

| Range | Programming resolution |

Accuracy (1 Year) ± (% reading+ offset) |

Typical Noise(RMS) 0.1 Hz-10Hz |

||||

| ±10 A1 | 1 μA | 0.03% + 2mA | 20 μA | ||||

| ±3 A | 1 μA | 0.03% + 2 mA | 20 μA | ||||

| ±1 A | 100 nA | 0.03% + 90 μA | 3 μA | ||||

| ±100 mA | 10 nA | 0.03% + 9 μA | 200 nA | ||||

| ±10 mA | 1 nA | 0.03% + 900 nA | 20 nA | ||||

| ±1 mA | 100 pA | 0.03% + 90 nA | 2 nA | ||||

| ±100 μA | 10 pA | 0.03% + 9 nA | 200 pA | ||||

| ±10 μA | 1 pA | 0.03% +1 nA | 30 pA | ||||

| ±1 μA | 100 fA | 0.03% + 200 pA | 5 pA | ||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

| Settling time | <100μs (typical) | ||||||

| Overshoot | <±0.1% (Typical.Normal.Step is 10 % to 90 % range, full range, resistive load) | ||||||

1、10 A range is available only for pulse mode, accuracy specifications for 10 A range are typical.

| Minimum programmable pulse width | 100 μs | ||||||

| Pulse width programming resolution | 1 μs | ||||||

| Pulse width programming accuracy | ±10 μs | ||||||

| Pulse width jitter | 2 μs | ||||||

| Pulse width definition | The time from 10 % leading to 90 % trailing edge as follows |

| Item | Maximums | Maximum pulse width | Maximum duty cycle | ||||

| 1 | 0.4 A/50 V | DC, no limit | 1 | ||||

| 2 | 1 A/20 V | DC, no limit | 1 | ||||

| 3 | 3 A/6.6 V | DC, no limit | 1 | ||||

| 4 | 10 A/20 V | 1ms | 0.05 | ||||

| 5 | 10 A/50 V | 400 μs |

0.02 |

Typical Pulse Performance(4W)

| Source | range | Typical rise time1 | Typical Settling Time2 | Test load | |||

|

Voltage |

50 V | 250 μs | 400 μs | NO load | |||

| 5 V | 40 μs | 100 μs | NO load | ||||

Current |

10 A~100 μA | 90 μs | 250 μs | Full load3 | |||

| 10 μA | 120 μs | 300 μs | Full load3 | ||||

| 1 μA | 300 μs | 600 μs | Full load3 | ||||

3、Test condition: Normal, resistive load 6V maximum output

| Output settling time1 | |||||||

| Fast2 | Normal | Slow | |||||

| 60 V | <120 μs | <300 μs | <1 ms | Time required to reach within 0.1 % of final value at open load condition. Step is 10 % to 90 % range |

|||

| 6 V | <30 μs | <50 μs | <300 μs | ||||

| 0.6 V | <30 μs | <50 μs | <300 μs | ||||

| 3 A~100 μA | <50 μs | <100 μs | <0.8 ms | value at short condition. Step is 10 % to 90 % range |

|||

| 10 μA | <100 μs | <150 μs | <0.8 ms | ||||

| 1 μA | <300 μs |

<400 μs |

<1 ms | ||||

1、Output transition speed:Fast, Normal, Slow. Users can adjust the APFC parameters based on the load characteristics to obtain precision, and fast output characteristics

2、Slow mode is recommended for overshoot sensitive equipment, Fast mode may have overshoot on output in some condition

Sampling rate and NPLC setting

| Setting | Range | ||||||

| NPLC | 0.00005 PLC ~ 10 PLC | ||||||

| Sampling Rate | 5 sps ~ 1 Msps |

| Add % of range using the following table for measurement with PLC < 1 | |||||||

| Range | |||||||

| 600 mV | 6 V | 60 V | 1 μA | 10 μA | 100 μA to 100 mA | 1 A to 3 A | |

| 0.1 | 0.02% | 0.01% | 0.01% | 0.02% | 0.01% | 0.01% | 0.01% |

| 0.01 | 0.30% | 0.03% | 0.02% | 0.20% | 0.04% | 0.02% | 0.02% |

| 0.001 | 3.20% | 0.40% | 0.10% | 2.50% | 0.40% | 0.03% | 0.03% |

Supplemental characteristics

| Sensing Modes | 2-wire or 4-wire (Remote-sensing) connections | ||||||

| Maximum sense lead resistance | 1 KΩ for rated accuracy | ||||||

| Max voltage between High Force and High Sense | 2 V | ||||||

| Maximum output voltage in output connector | >range 105%(60 V range>60.5 V) | ||||||

| Sweep | Sweep step time: from 20μs to 16s, Max: 8K point | ||||||

| Auto range | Support,turn off output is recommended for overshoot sensitive equipment before range change | ||||||

| Source delay | Support,It is recommended that users set appropriate source delay to obtain higher accuracy | ||||||

| Over temperature protection |

The output will be turned off (also disable operation) when the SMU internal temperature is detected higher than 85 degrees. When the temperature returns to less than 65 degrees, operation recover |

||||||

| Other abnormal protection | Power reset,recover operation or hardware damage |

文档下载

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Democode

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password