PXIe SMU

S2014C

12 channel PXIE precision power supply/measurement unit

Semight Instruments S2014C A compact and cost-effective 12 channel PXIE power supply/measurement unit that can simultaneously output and measure voltage and current, with a maximum output of ± 4.5V and ± 10 mA (DC/pulse). It supports traditional SMU SCPI commands, making test code migration easy and fast. It also supports existing large factory PXIE boxes, It can support multi card synchronization and be integrated into production testing systems to improve system testing efficiency and reduce costs.

Features

High range, high-speed measurement

±4.5 V、±10 mA(DC/Pulse)

Wide pulse width range

Min: 100 μ Resolution: 1 μ S

Adaptive PFC system

Utilizing Adaptive PFC

12 channel testing system

Based on standard PXIE chassis,Functions and advantages

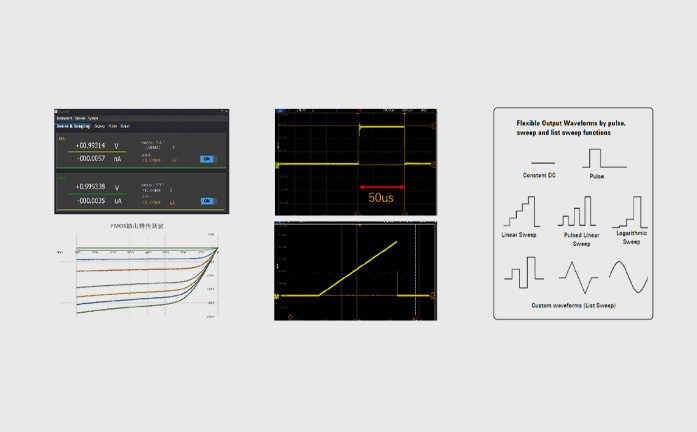

5 functions in one

Voltage source

Can test various devices

Capture more measurement data

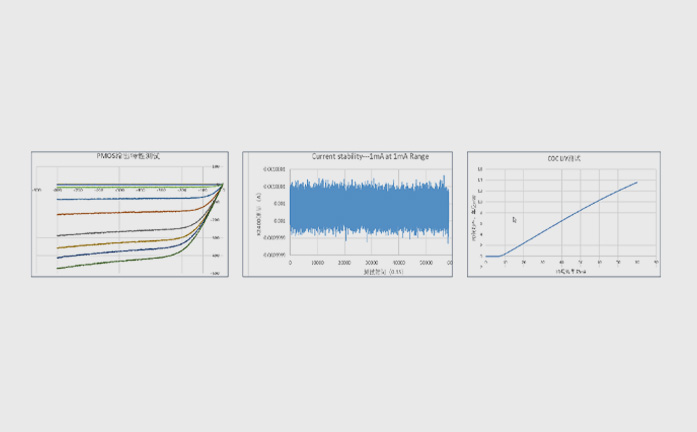

♦ 6 Half bit digital resolution: The accuracy is equivalent to a 6-and-a-half bit digital multimeter;

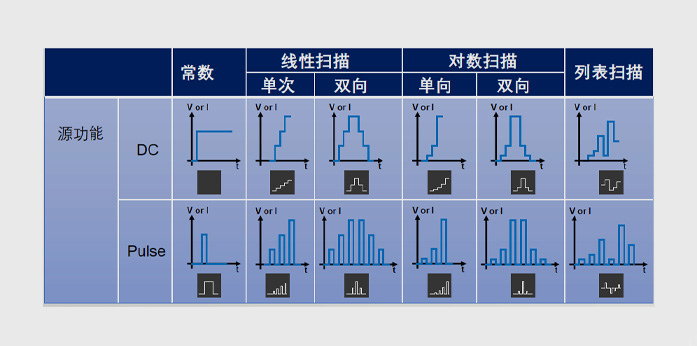

Rich scanning functions

Voltage Indicators

|

Voltage Precision

|

Measuring Range |

Measuring Resolution |

Precision (1 year) ± (% Reading + Bias) |

Typical Noise (RMS) 0.1 Hz-10Hz |

|

±4.5V |

1 μV |

0.02%+100μV |

50 μV |

|

|

Temperature Coefficient |

±(0.15 × Precision Indicator)/°C (0℃-18℃,28℃-50℃) |

|||

|

Setting Time |

<200μs (Typical Value) |

|||

|

Overshoot |

<±0.1% (Typical Value,Normal, Step Range is 10% to 90%,Full Scale Point,Resistive Load Test) |

|||

1,All channel outputs are electrically isolated from earth, but each channel output shares a common ground (LO).

Current Indicators

|

Current Precision

|

Measuring Range |

Measuring Resolution |

Precision (1 year) ± (% Reading + Bias) |

Typical Noise (RMS) 0.1 Hz-10Hz |

|

±10 mA |

10 nA |

0.05%+5μA |

20 nA |

|

|

±1 mA |

1 nA |

0.05%+500nA |

10 nA |

|

|

±100 μA |

100 pA |

0.05%+50nA |

200 pA |

|

|

±10 μA |

10 pA |

0.05%+5nA |

100 pA |

|

|

Temperature Coefficient |

±(0.15 × Precision Indicator)/°C (0℃-18℃,28℃-50℃) |

|||

|

Setting Time |

<2ms (Typical Value) |

|||

|

Overshoot |

<±0.1% (Typical Value,Normal, Step Range is 10% to 90%,Full Scale Point,Resistive Load Test) |

|||

1、All channel outputs are electrically isolated from earth, but each channel output shares a common ground (LO)

Pulse Source Indicators (4- lines)

|

Minimum Programmable Pulse-width |

250μs |

|

Pulse-width Programming Resolution |

1μs |

|

Pulse-width Programming Precision |

±10μs |

|

Pulse-width Jitter |

2μs |

|

Pulse-width Definition |

The time from the 10 % leading edge to the 90 % trailing edge is shown in the following figure |

Pulse source rise time (4 lines)

|

Output |

Maximum Output |

Typical Rise Time 1 |

Typical stabilization time 2 |

Test Load |

|

Voltage Source |

4.5 V |

100 μs |

200 μs |

No-Loaded |

|

Current Source

|

10mA |

60 μs |

100 μs |

Full-Loaded 3 |

|

1mA |

800 μs |

1 ms |

Full-Loaded 3 |

|

|

100uA |

120 μs |

180 μs |

Full-Loaded 3 |

|

|

10 μA |

1.5 ms |

2 ms |

Full-Loaded 3 |

1、Time required for the pulse leading edge from 10% to 90%.

2、Time required for the pulse to reach 1% of the final value.

3、Test conditions:normal pure resistance full load voltage rises to 4.5V

Sampling rate and NPLC setting

|

Configuration Method |

Configuration Range |

|

NPLC |

0.00005PLC ~ 10PLC |

|

Sampling Rate |

5sps ~ 1.0Msps |

Sampling rate and NPLC setting

Percentage of range with increased tolerance

|

PLC

|

Measuring Range |

||||

|

4.5V |

10μA |

100μA |

1mA |

10mA |

|

|

0.1 |

0.01% |

0.02% |

0.01% |

0.02% |

0.01% |

|

0.01 |

0.3% |

0.2% |

0.04% |

0.04% |

0.02% |

|

0.001 |

3.2% |

2.5% |

0.4% |

0.3% |

0.03% |

Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password