High precision desktop source meter

S2022H

8-Channel Precision Source Meter

The S2022H precision source meter is compact and cost-effective bench-top Source/Measure Units (SMUs) with the capability to source and measure both voltage and current. These capabilities make the S2022H ideal for IV (current versus voltage) measurement tasks that require both high resolution and accuracy.

Features

High range

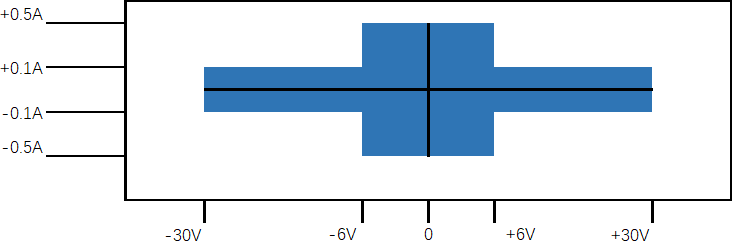

Range: ± 30 V, ± 500 mA (DC)

High resolution

The minimum measurement resolution can reach 100 pA/100 μV

High sampling rate

Supports up to 500K ADC sampling rate

Threshold trigger

Hardware high-speed IO, capable of threshold triggering, enabling efficient interaction between output measurement values and user systemsFeatures and Benefits

I-V output capability

|

Voltage programming accuracy |

Range |

Programming Resolution |

Accuracy (1 year) ± (% reading+offset) |

Typical noise (RMS) 0.1 Hz-10 Hz |

|

± 30 V |

1 mV |

0.03%+4 mV |

1000 μV |

|

|

± 6 V |

200 μV |

0.03%+1 mV |

100 μV |

|

|

Temperature coefficient |

± (0.15 x accuracy)/℃ (0 ℃ -18 ℃, 28 ℃ -50 ℃) |

|||

|

Channel1 |

CH1 to CH8 |

|||

|

Output power |

Ch1 Ch4: 3 W per channel and 6W total Ch5 Ch8: 3 W per channel and 6W total |

|||

|

Setting Time |

< 200μs (typical) |

|||

|

Overshoot |

< ± 0.1% (Typical, Normal, Step is 10% to 90%, full range, resistive load) |

|||

|

Noise 10Hz-20MHz |

6V voltage source, 0.5 A resistive load,< 3 mVrms |

|||

1. Channels are isolated from earth ground, but ch1 to ch4 share a common LO. but ch5 to ch8 share a common LO.

|

Current programming accuracy |

Range |

Programming Resolution |

Accuracy (1 year) ± (% reading+offset) |

Typical noise (RMS) 0.1 Hz-10 Hz |

|

± 500 mA1 |

20 μA |

0.05%+100 μA+ Vo * 25 μA |

10 μA |

|

|

± 100 mA |

4 μA |

0.05%+10 μA+ Vo * 5 μA |

1 μA |

|

|

± 10 mA |

400 nA |

0.05%+5 μA+ Vo * 500 nA |

100 nA |

|

|

± 1 mA |

40 nA |

0.05%+500 μA+ Vo * 50 nA |

10 nA |

|

|

± 100 μ A |

4 nA |

0.05%+50 nA+ Vo * 5 nA |

1 nA |

|

|

± 10 μA |

400 pA |

0.05%+20 nA+ Vo * 500 pA |

150 pA |

|

|

Temperature coefficient |

± (0.15 x accuracy)/℃ (0 ℃ -18 ℃, 28 ℃ -50 ℃) |

|||

|

Channel2 |

CH1 to CH8 |

|||

|

Output power |

Ch1 Ch4: 3 W per channel and 6W total Ch5 Ch8: 3 W per channel and 6W total |

|||

|

Set Time |

< 300 μs (typical) |

|||

|

Overcharge |

< ± 0.1% (Typical, Normal, Step is 10% to 90%, full scale point, resistive load test) |

|||

1. 500mA range is available only for 6V voltage range

2. Channels are isolated from earth ground, but ch1 to ch4 share a common LO. but ch5 to ch8 share a common LO.

|

Voltage measurement accuracy |

Range |

Measurement Resolution |

Accuracy (1 year) ± (% reading+offset) |

|

± 30 V |

300 μV |

0.03%+4 mV |

|

|

± 6 V |

60 μV |

0.03%+1 mV |

|

|

Temperature coefficient |

± (0.15 x accuracy)/℃ (0 ℃ -18 ℃, 28 ℃ -50 ℃) |

||

|

Current measurement accuracy |

Range |

Measurement Resolution |

Accuracy (1 year) ± (% reading+offset) |

|

± 500 mA1 |

10 μA |

0.05%+100 μA+ Vo * 25 μA |

|

|

± 100 mA |

1 μA |

0.05%+10 μA+ Vo * 5 μA |

|

|

± 10 mA |

100 nA |

0.05%+5 μA+ Vo * 500 nA |

|

|

± 1 mA |

10 nA |

0.05%+500 nA+ Vo * 50 nA |

|

|

± 100 μA |

1 nA |

0.05%+50 nA+ Vo * 5 nA |

|

|

± 10 μA |

100 pA |

0.05%+20 nA+ Vo * 500 pA |

|

|

Temperature coefficient |

± (0.15 x accuracy)/℃ (0 ℃ -18 ℃, 28 ℃ -50 ℃) |

||

1.500mA range is available only for 6V voltage range

|

Source |

Range |

Output setting time |

Condition |

||

|

Fast 1, 2 |

Normal1 |

Slow1 |

|||

|

Voltage |

30 V |

< 400 μs |

< 1.5ms |

< 2.8 ms |

Time required to reach within 0.1 % of final value at open load condition. Step is 10 % to 90 % range |

|

6 V |

<250 μs |

<780 μs |

<2.8 ms |

||

|

Current |

± 500 mA |

<50 μs |

<330 μs |

<2.5 ms |

Time required to reach within 0.1 % of final value at short condition. Step is 10 % to 90 % range |

|

±100 mA |

<50 μs |

<270 μs |

<2.5 ms |

||

|

±10 mA |

<50 μs |

<270 μs |

<2.5 ms |

||

|

±1 mA |

<100 μs |

<290 μs |

<2.5 ms |

||

|

±100 μA |

<150 μs |

<5 ms |

<2.5 ms |

||

|

±10 μA |

<250 μs |

<3 ms |

<2.5 ms |

||

1. Output transition speed:Fast, Normal, Slow

2. Slow mode is recommended for overshoot sensitive equipment, Fast mode may have overshoot on output in some condition

文档下载

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Democode

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password