Q&A

Common Problem

?Q

The module aging and to aging oven cannot reach the reasonable set temperature

?Q

Module aging and to aging: click "start aging" on the software, and the integrated machine occasionally appears black screen during contactor startup.

?Q

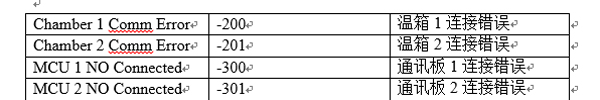

In the process of module aging and to aging, the software reports an error of 300 / 200 / 301 / 201 occasionally

?Q

Module aging and to aging: click "start aging" on the software, and the software reports an error of 200 / 201 during contactor startup.

?Q

Module aging and to aging click start aging on the software, and the software reports an error of 300 / 200 / 301 / 201.

The reasons for error reporting are as follows:

Cause possibility analysis

The IP address of the oven PLC or communication board is set incorrectly or the MAC address conflicts;

resolvent

Manually modify the IP address of the PLC or modify the IP address of the communication board with a gadget;

?Q

Description of TO and module aging drive board indicator

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password