Laser Diode Test

CT8201

RT & HT Die tester

Features

Fully automated and intelligent integrated solutions

Highly integrated and fully automated solution covering very complex testing processes

High efficiency

Improve efficiency and reduce potential risks of human involvement

Maintenance and upgrades are very simple

All mechanical parts can be returned to the factory independently

Easy to use

Automatic alarm status and prompt display,Features and Benefits

Fully automated and intelligent integrated solutions

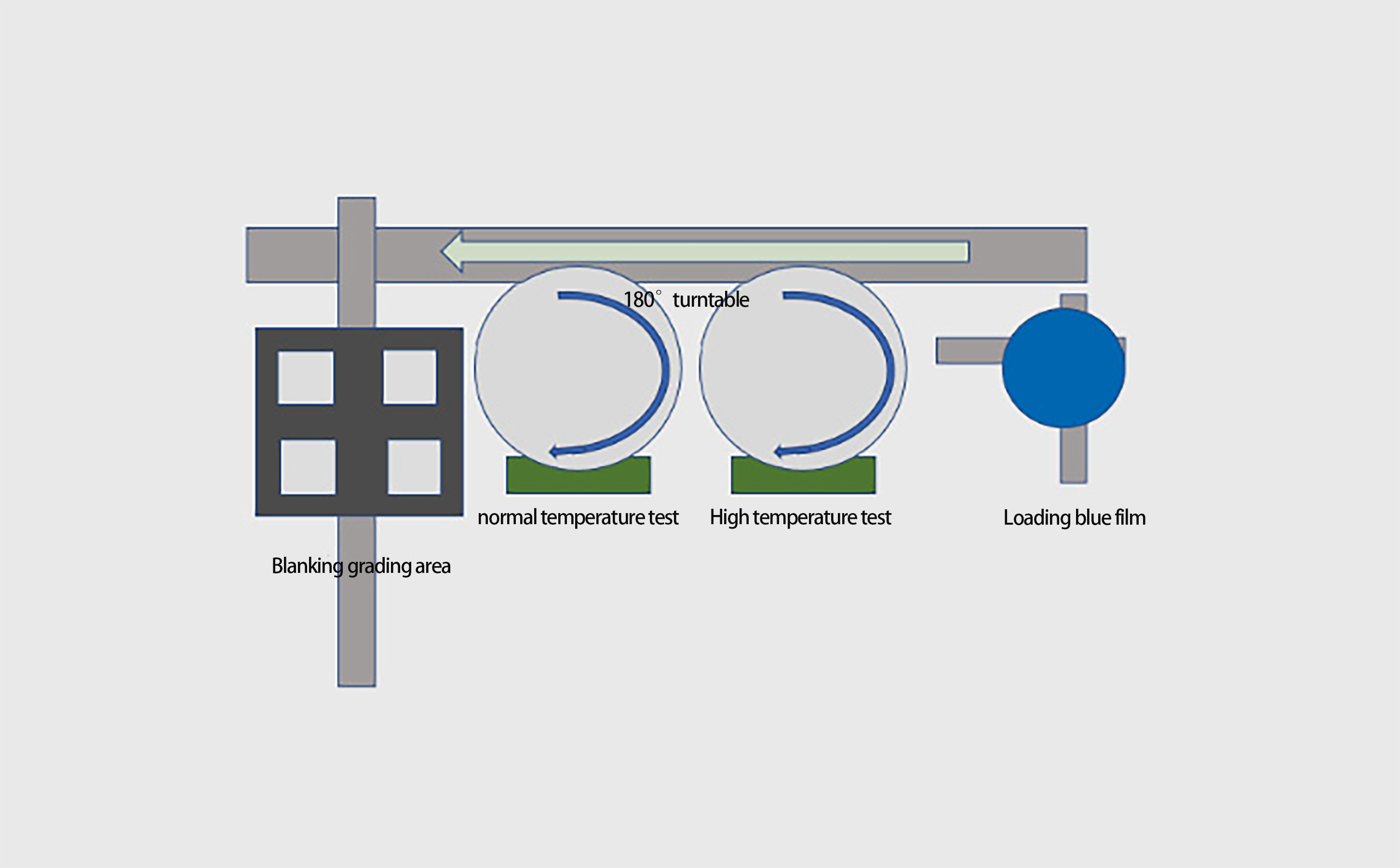

Loading module

This module consists of thimble Z module, X/Y motion module, and blue film rotation module 4 sub-function modules. Pickup function.

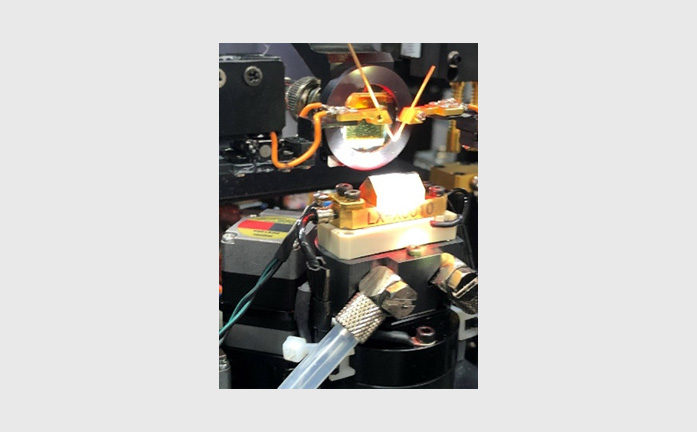

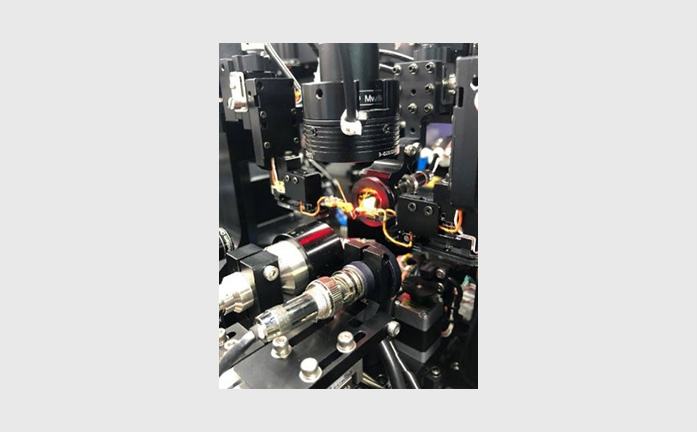

High temperature and normal temperature test module

This module consists of a hollow rotating platform, two 3-axis chip calibration modules on the front and back, and a 3-axis light detection module, with an ID/position recognition camera above the module, and Power on the probe to adjust the module, complete the calibration of the position and angle after feeding, and power on the chip test. The PD/collimator uses a motion axis for fast switching of functions.

Camera and probe power-on module

The loading camera on the right side of the device is matched with the loading module to complete the loading recognition function of the Chip (different functional components can be matched according to the requirements of incoming materials) The camera above the high/normal temperature test module (in the middle of the device), after the chip feeding action is completed, the position calibration of the chip is completed by taking multiple pictures with the 3-axis motion module (the high temperature camera synchronously completes the ID identification of the chip).

Blanking binning module

The blanking module is equipped with 4 tray placement areas, which can support 4,6-inch blue films, Or customize compatible unloading carriers according to customer needs.| Parameter Type | Parameter name | Parameter index |

| System parameters | Chip type | Support DFB, EML and EML+SOA chips |

| Chip size | L&W≥150 μm, H≥80~150 μm | |

Test Seats |

2 | |

| Test items | Front/back IL, WL | |

| Test parameters | Ith, Se, Iop, Pf, Vf, Kink, Rs, IRoll, λc, SMSR etc. | |

| OCR | Auto OCR |

|

| Nip | Specially designed suction nozzle structure, first peeled from the material box, and then sucked up | |

Loading Container |

1 6-inch blue tap |

|

Unloading Container | 4 6-inch blue taps |

|

Sorting |

Support any requirements customer need |

|

| Standard sample control | The software supports the standard sample control function. If the standard sample is tested on the local machine unit exceeding the time cycle (configurable), the system will automatically give an alarm | |

| Test configuration control | The software supports test configuration control, including test instruments, test algorithms, test sequences, test results judgment, etc. | |

| Test Data | Support all test data requested by users/support MES related requirements | |

| Electrical indicators | SMU Type | Semight self-developed SMU or other specified types |

DC Current |

3 A | |

| I/V source resolution | 10 fA/100 nV | |

| I/V Measurement resolution | 10fA/100nV Minimum Supply Resolution (6½ digits) | |

| Voltage range | 70 V | |

| Pulse current | 10 A | |

| Overcharge under normal operating | No EOS | |

| Under normal operating | No EOS | |

Overshoot under Abnormal Operation |

No EOS | |

Undershoot under Abnormal Operation |

No EOS | |

| Optical index | Detector Type | Ge |

| Wavelength range | 800~1700 nm | |

| Optical power measurement range | 10 μW-25 mW(>25 mW with attenuation plate ) | |

| Optical power measurement accuracy | 0.1 dB | |

Optical Spectrum Range |

1250-1650 nm (850 is an option) | |

Optical Spectrum Accuracy |

0.1nm | |

| Power coupling efficiency | Coupled power >-15 dBm | |

| 0.2 dB | ||

| Temperature control index | Temperature control method | TEC |

| Temperature range |

25~95 ℃ |

|

| Temperature zone | 40 ℃/min | |

| Temperature drop rate | 2 independent temperature control zones (dual stage) | |

Ramp up speed |

40 ℃/min | |

Ramp down speed |

40 °C/min | |

| Temperature accuracy | ±0.5 ℃ | |

| Temperature stability | ±0.2 ℃ | |

System Parameter |

Ith Repeatability | ±1% |

| Power repeatability | ±2% | |

| Wavelength repeatability | <±0.2 nm | |

| SMSR Repeatability | <3 dB | |

| OCR success rate | 99% | |

| Test time | <6s to finish all operations, including loading, OCR, 1 times LIV, 3 times Spectrum, unloading and sorting |

Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password