High speed Transceiver ATE

ATE8104/ATE8108

Optical Transceiver Tester

The ATE (Automatic Test Equipment) integrated testing system combines various test cases for transceiver and integrates the sub-functional modules according to the functional requirements ratio. Users can flexibly configure the system according to their actual testing needs, improving the utilization of transceiver test instruments and effectively reducing testing costs. The system's integrated software encapsulates various parameters in transceiver testing, allowing users to quickly build the test system like building blocks and accelerate the mass production introduction of new products.

The entire system adopts multi-channel parallel testing, combining software and hardware to fully utilize the functions of instruments and software, significantly improving the testing efficiency of each unit product.

Features

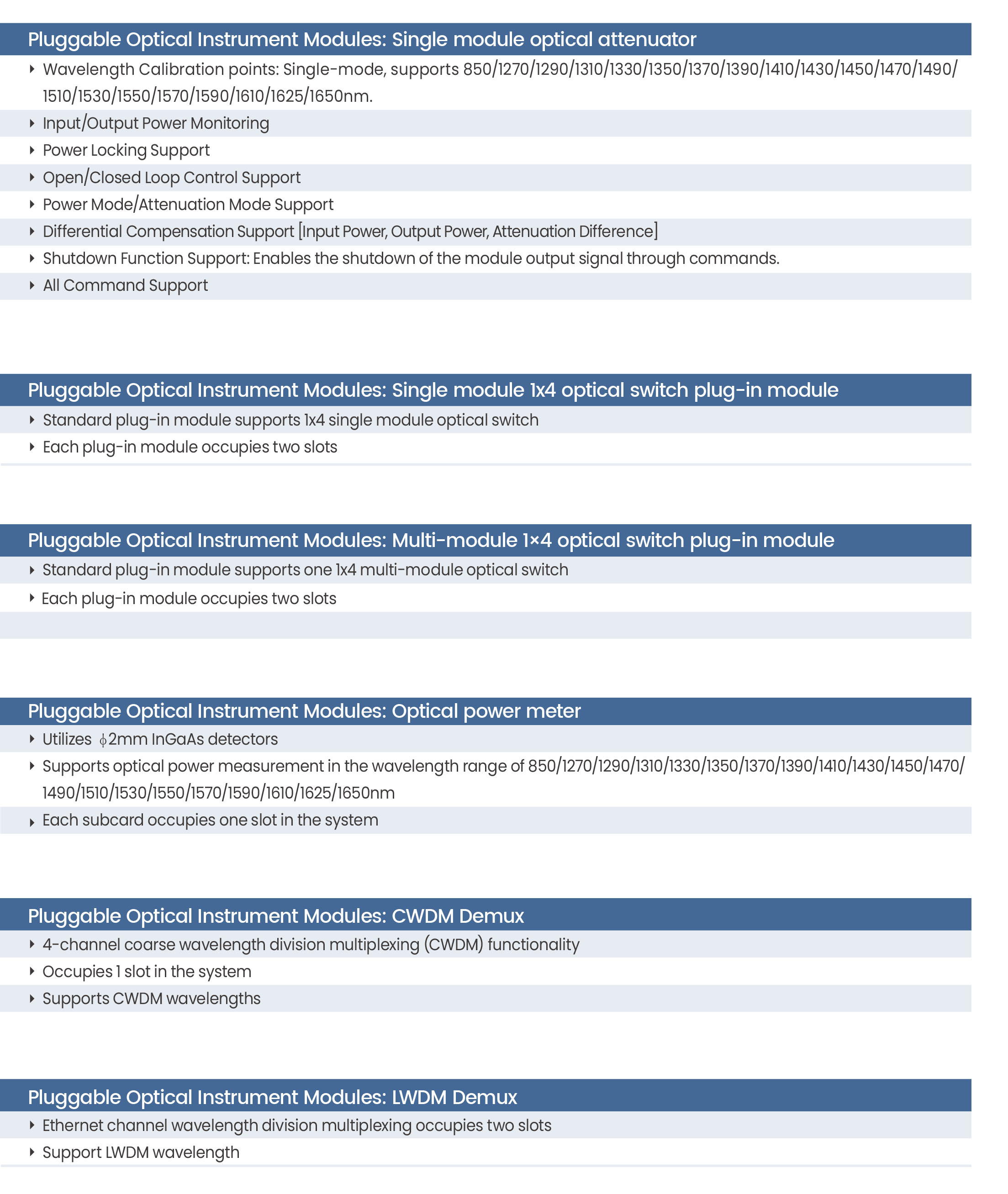

Plug-in Optical paltform

Each functional module is encapsulated into a plug-in module, allowing users to flexibly optimize hardware configuration

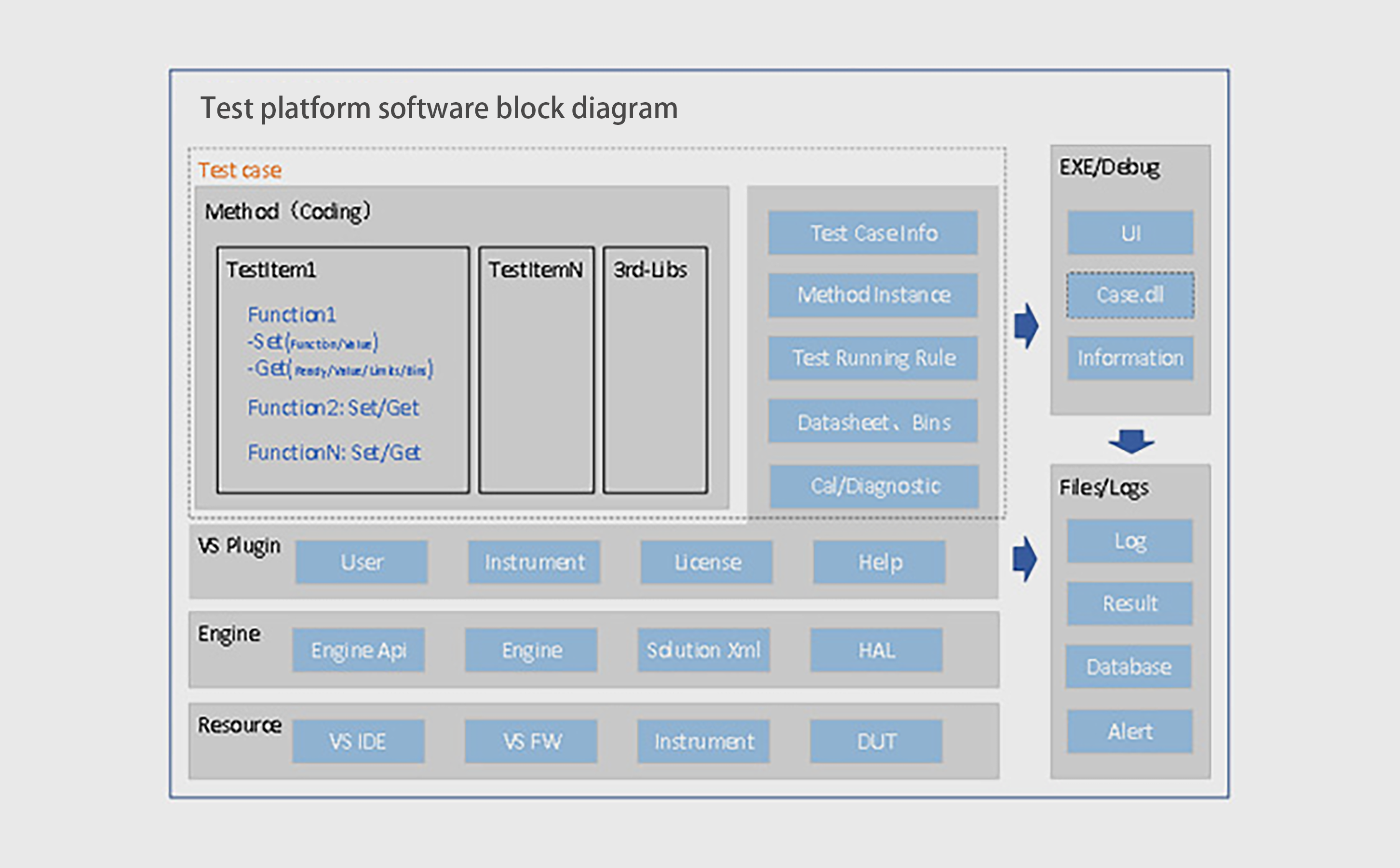

Software platform

The software is highly encapsulated, and each sub-function module of the software can be arbitrarily called and combined at will

Multi-channel parallel testing

Increase the number of channels, parallel test, greatly improve test efficiency

Integrated TEC temperature control system

Support module -10~85℃ temperature cycle testFeatures and Benefits

Plug-in optical platform

Integrate common optical instruments Optical power meter/optical switch/optical decay/optical CDR Integrate common passive components MUX/DEMUX/Splitte Flexible configuration

Integrated thermal cycling test system

TEC-based temperature control system

Platform software system

Subfunction Modularization

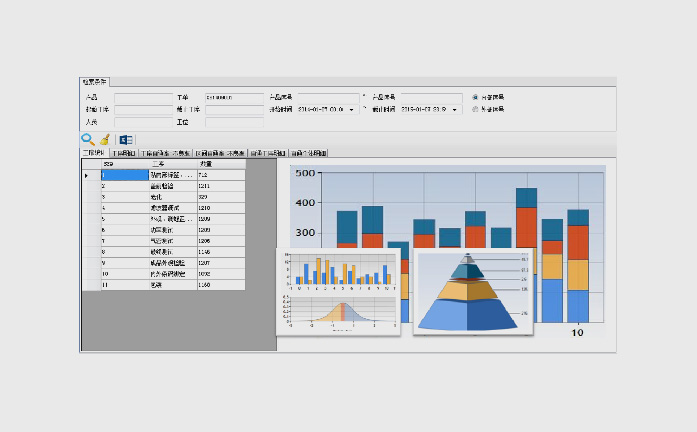

Automatically generate software reports

Pass rate analysis

文档下载

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Democode

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password