Standard desktop source meter

S3022F

Dual-Channel Precision SMU

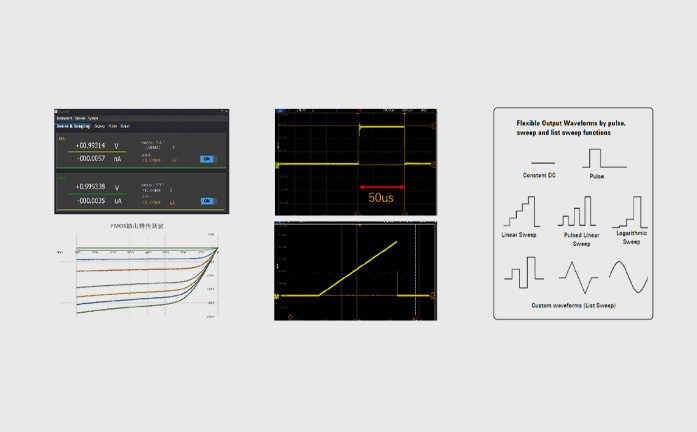

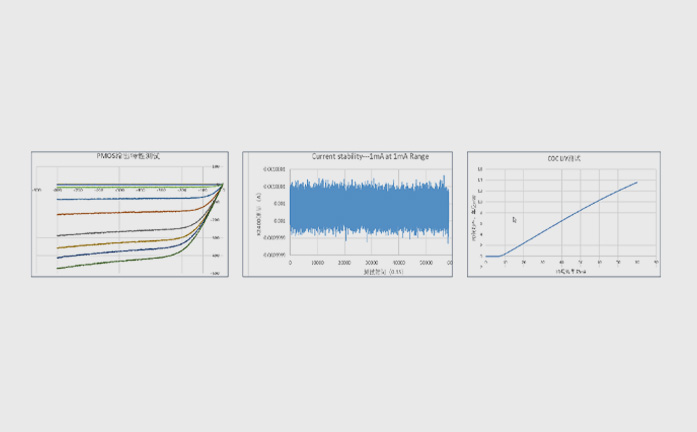

The S3022F precision source meter is compact and cost-effective bench-top Source/Measure Units (SMUs) with the capability to source and measure both voltage and current. These capabilities make the S3022F ideal for a wide variety of IV (current versus voltage) measurement tasks that require both high resolution and accuracy.

Feature

High range

Range:±200 V、±3 A(DC)、±10A(pulse)

High resolution

The minimum measurement resolution can reach 100 fA / 100 nV

High sampling rate

Up to 1M ADC sampling rate

Threshold trigger

Hardware high-speed IO, which can realize threshold triggering and realize efficient interaction between output measured value and user systemFunctions and advantages

Integration of five functions

Integration of five functions

1. The first and third quadrants are the source: the actual polarity of the output V/I follows the source setting;

2. The second and fourth quadrants are the load: CC and CV cooperate, when the load is used, the load setting polarity is opposite to the source polarity;

Can test various equipment

Capture more measurement data

♦ 6.5-bit digital resolution: accuracy equivalent to6-and-a-half digitsA multimeter;

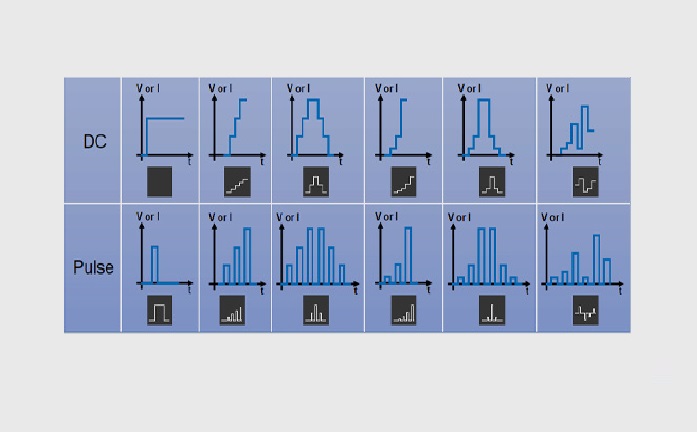

Rich scanning function

Voltage programming accuracy |

Range | Programming resolution |

Accuracy (1 Year) ± (% reading+ offset) |

Typical Noise (RMS) 0.1 Hz-10 Hz |

|||

| ±200 V | 1 mV | 0.02%+30 mV | 1.5 mV | ||||

| ±20 V | 100 μV | 0.02%+2 mV | 160 μV | ||||

| ±6 V | 50 μV | 0.02%+500 μV | 36 μV | ||||

| ±200 mV | 1 μV | 0.02%+120 μV | 4 μV | ||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

| Maximum output power | 30W: ±20 V@1.5 A, ±200 V@0.1 A; 18 W: ±6 V@3 A | ||||||

| Settling time | <800 μs (typical) | ||||||

| Overshoot | <±0.1% (Typical. Normal mode. Step is 10 % to 90 % range, full range, resistive load) | ||||||

| Noise 10Hz-20MHz | 6 V voltage source, 3 A resistive load, <3 mVrms | ||||||

Current programming accuracy |

Range | Programming resolution |

Accuracy (1 Year) ± (% reading+ offset) |

Typical Noise (RMS) 0.1 Hz-10Hz |

|||

| ±10 A1 | 50 μA | 0.4% + 40 mA | NA | ||||

| ±3 A | 15 μA | 0.05% + 2 mA | 40 μA | ||||

| ±1.5 A | 10 μA | 0.02% + 500 μA | 20 μA | ||||

| ±150 mA | 1 μA | 0.02% + 25 μA | 5 μA | ||||

| ±15 mA | 100 nA | 0.02%+6 μA | 700 nA | ||||

| ±1.5 mA | 10 nA | 0.02% + 250 nA | 16 nA | ||||

| ±150 μA | 1 nA | 0.02% + 25 nA | 1 nA | ||||

| ±15 μA | 100 pA | 0.02% + 3 nA | 140 pA | ||||

| ±1.5 μA | 10 pA | 0.03% + 450 pA | 25 pA | ||||

| ±150 nA | 1 pA | 0.05%+250 pA | 5 pA | ||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

| Maximum output power | 30W: ±20V@1.5A, ±200V@0.1A; 18W: ±6 V@3A | ||||||

| Settling time | <500 μs (typical) | ||||||

| Overshoot | <±0.1% (Typical. Normal mode. Step is 10 % to 90 % range, full range, resistive load) | ||||||

1,10 A range is available only for pulse mode, accuracy specifications for 10 A range are typical.

Voltage measurement accuracy |

Range | Measurement resolution |

Accuracy (1 Year) ± (% reading+ offset) |

||||

| ±200 V | 100 μV | 0.02% + 30 mV | |||||

| ±20 V | 10 μV | 0.02% + 2 mV | |||||

| ±6 V | 1 μV | 0.02% + 500 μV | |||||

| ±200 mV | 100 nV | 0.02% + 120 μV | |||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

Current measurement accuracy |

Range | Measurement resolution | Accuracy (1 Year)± (% reading+ offset) | ||||

| ±10 A1 | 10 μA | 0.4% + 25 mA | |||||

| ±3 A | 10 μA | 0.05% + 2 mA | |||||

| ±1.5 A | 1 μA | 0.02% + 500 μA | |||||

| ±150 mA | 100 nA | 0.02% + 25 μA | |||||

| ±15 mA | 10 nA | 0.02% + 6 μA | |||||

| ±1.5 mA | 1 nA | 0.02% + 250 nA | |||||

| ±150 μA | 100 pA | 0.02% + 25 nA | |||||

| ±15 μA | 10 pA | 0.02% +3 nA | |||||

| ±1.5 μA2 | 1 pA | 0.03% + 450 pA | |||||

| ±150 nA2 | 100 fA | 0.05% + 250 pA | |||||

| Temperature coefficient | ±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

| Range | Measurement resolution | Test current |

Accuracy (1 Year) ± (% reading+ offset) |

||||

| 1 Ω | 1 μΩ | 1.5 A | 0.073% +0.3334 mΩ | ||||

| 10 Ω | 10 μΩ | 150 mA | 0.057% + 3.334 mΩ | ||||

| 100 Ω | 100 μΩ | 15 mA | 0.08% + 33.34 mΩ | ||||

| 1 kΩ | 1 mΩ | 1.5 mA | 0.057% + 333.4 mΩ | ||||

| 10 kΩ | 10 mΩ | 150 μA |

0.057% + 3.334 Ω | ||||

| 100 kΩ | 100 mΩ | 15 μA | 0.06% + 33.34 Ω | ||||

| 1 MΩ | 1 Ω | 1.5 μA | 0.06% + 333.4 Ω | ||||

| 10 MΩ | 10 Ω | 0.15 μA | 0.35% + 3.334 kΩ | ||||

| 100 MΩ | 100 Ω | 0.05 μA | 0.95% + 10 kΩ | ||||

Temperature coefficient |

±(0.15 × accuracy)/°C (0℃-18℃,28℃-50℃) | ||||||

|

Source I mode, manual Ohm measurement (4-wire) |

Total error = Vmeas/Isrc = R reading x (gain error % of V range + gain error % of I range + offset error of I source range/Isrc value %) + (offset error of V measure range/Isrc value) Example:I source value=1.5A at 1.5A range V measure range=6V range Total error(% reading + offset) =(0.02%+0.02%+500μA/1.5A)+(500μV/1.5A) ≈ 0.073%+0.3334mΩ | ||||||

Pulse source specifications (4W)

| Minimum programmable pulse width | 100 μs | ||||||

| Pulse width programming resolution | 1 μs | ||||||

| Pulse width programming accuracy | ±10 μs | ||||||

| Pulse width jitter | 2 μs | ||||||

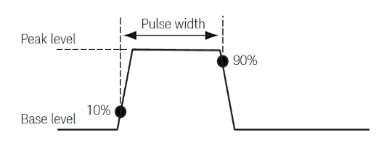

| Pulse width definition | The time from 10 % leading to 90 % trailing edge as follows |

| Item | Maximums | Maximum pulse width | Maximum duty cycle | ||||

| 1 | 0.15 A/200 V | DC,no limit | 1 | ||||

| 2 | 1.5 A/20 V | DC,no limit | 1 | ||||

| 3 | 3 A/6 V | DC,no limit | 1 | ||||

| 4 | 3 A/20 V | 1 ms | 0.1 | ||||

| 5 | 10 A/6 V | 1 ms | 0.1 |

| Source | range | Typical rise time1,3 | Typical Settling Time2,3 | Test load | |||

Voltage |

200 V | 600 μs | 1.5 ms | No load | |||

| 20 V | 200 μs | 360 μs | No load | ||||

| 6 V | 160 μs | 300 μs | No load | ||||

Current |

10 A | 140 μs | 320 μs | Full load | |||

| 3 A | 120 μs | 280 μs | Full load | ||||

| 1.5 A | 120 μs | 280 μs | Full load | ||||

| 150 mA | 120 μs | 280 μs | Full load | ||||

| 15 mA | 120 μs | 280 μs | Full load | ||||

| 1.5 mA | 120 μs | 280 μs | Full load | ||||

I-V Out capability

| Setting | Range | ||||||

| NPLC | 0.00005 PLC ~ 10 PLC | ||||||

| Sampling Rate | 5 sps ~ 1 Msps |

文档下载

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Democode

DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册  DS70000数据手册

DS70000数据手册 Similar recommendation

mailbox

Service hotline

follow

full name

e-mail address

Email verification code

Telephone

password

Confirm Password

e-mail address

Email verification code

New Password

Confirm Password